厂商 :常州蓝阳环保设备有限公司

江苏 常州- 主营产品:

- 活性炭吸附箱

- 废气处理设备

- 废气净化设备

联系电话 :13179310883

商品详细描述

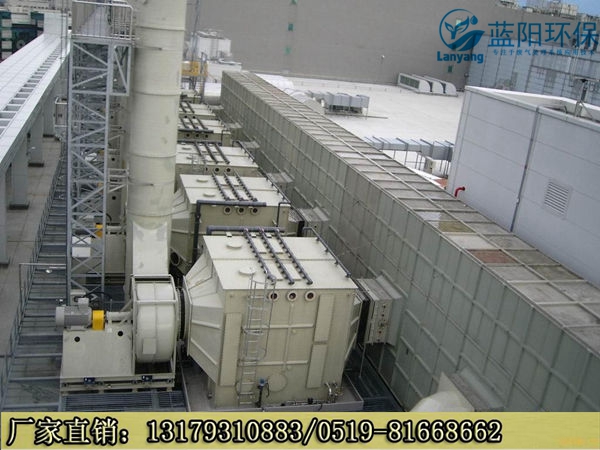

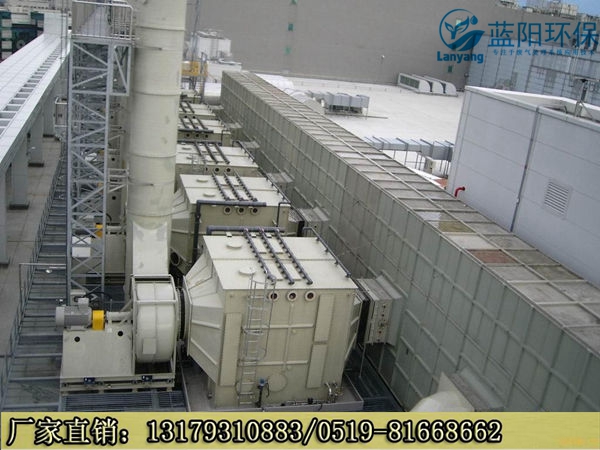

电子厂废气处理-鱼粉厂废气处理-电镀厂废气处理-皮革厂废气处理 厂家生产,蓝阳环保,咨询热线:0519-81668662,13179310883,欢迎您的来电垂询!~~

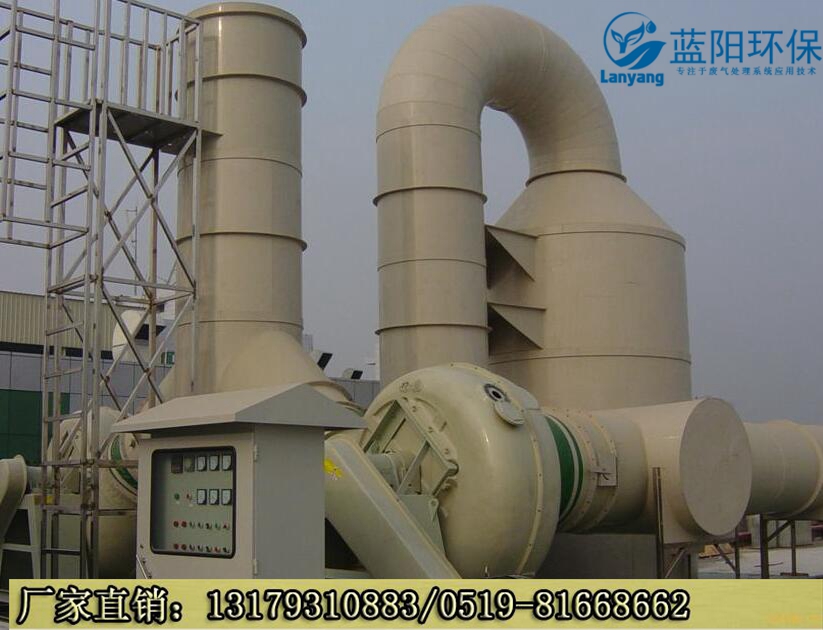

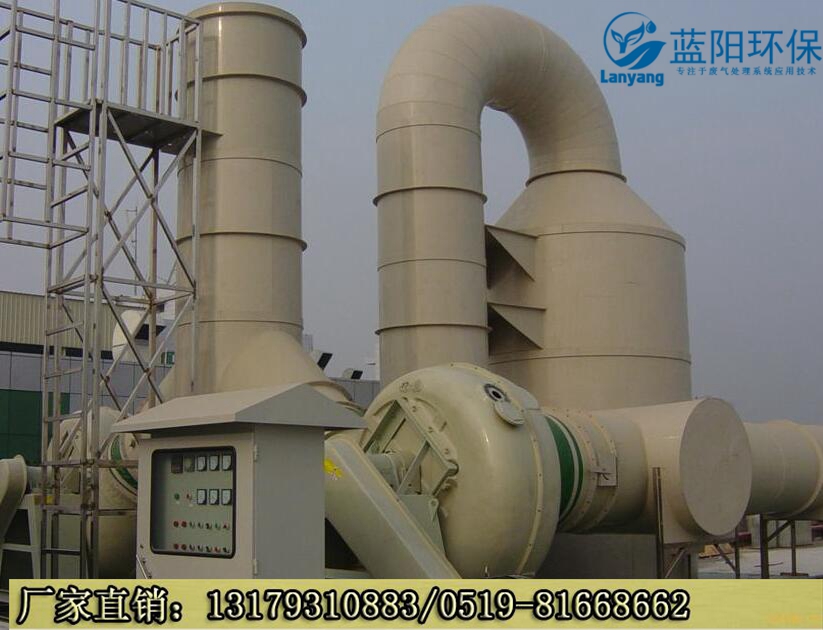

酸气净化塔:

一、概述:

酸雾净化塔适用于硫酸、硝酸、氢氟酸、盐酸等工艺操作过程中产生酸性气体的废气治理。BST型酸雾净化塔是一种填料式气液传质园形结构的处理塔。填料层为二级φ25-φ38聚丙烯阶梯环,每级填料主为500~800mm。本设备采用喷嘴雾布液。挡水板为90°、4折板。处理塔由三个部分组成:下段一液箱段;中段一填料喷淋再填料喷淋段;上段一挡水段。净化塔设有角钢加固框架和检修梯,设有液下泵等溶液循环系统。吸收液一般采用5~10%NaOH,当处理硝酸气体时,建议加Na2S溶液以提高净化效率。

本设备不配带带排风机,但亦可按用户要求代购。

本设备具有净化效率高、结构紧凑,占地面积小、耐腐蚀、耐老化性能好,重量轻,便于安装、运输。

设备特点:

1).吸附率高,活性炭纤维用量少,造价低。

活性炭纤维吸附、脱附速度快,每一次循环的吸附时间短,装填量小,设备精巧,投资低。

2).回收溶剂品质高

吸附和解吸的时间短,温度相对不高,不促使有机物分解,因此回收溶剂可直接回用生产。

3).运行能耗低、费用低。

活性炭纤维的脱附、再生能耗低,缠绕芯的气流阻力小、风机功率小,设备耗能低。

4).低成本实现大风量处理。

根据多年实践经验总结进化的先进运行工艺专利技术,能够配置最少的吸附器个数而达到最大的废气处理能力,从而降低了造价、减少了用户的占地面积。

5).安全可靠、适用于有爆炸危险场所。

采用防爆风机、防爆泵。控制柜、气动柜采用正压防爆技术,外部信号通过安全栅连接,系统接地,确保了装置的安全性。

6).不仅可以治理污染,而且回收的物品会产生经济效益,短期内即可收回投资。

uv光解氧化除臭设备 废气处理设备uv高效光解净化设备

一、利用特制的高能UV紫外线光束照射恶臭气体,裂解恶臭气体如:氨、三甲胺、硫化氢、甲硫氢、甲硫醇、甲硫醚、二甲二硫、二硫化碳和苯乙烯,硫化物H2S、VOC类,苯、甲苯、二甲苯的分子键。

二、利用高臭氧分解空气中的氧分子产生游离氧,即活性氧,因游离氧所携正负电子不平衡所以需与氧分子结合,进而产生臭氧,使呈游离状态的污染物分子与臭氧氧化结合成小分子无害或低害的化合物。如CO2、H2O等。UV+O2→O-+O*(活性氧)O+O2→O3(臭氧)。

uv光解氧化除臭设备 废气处理设备uv高效光解净化设备技术原理

一、本产品利用特制的高能高臭氧UV紫外线光束照射恶臭气体,改变恶臭气体如:氨、三甲胺、硫化氢、甲硫氢、甲硫醇、甲硫醚、二甲二硫、二硫化碳和苯乙烯,硫化物H2S、VOC类,苯、甲苯、二甲苯的分子链结构,使有机或无机高分子恶臭化合物分子链,在高能紫外线光束照射下,降解转变成低分子化合物,如CO2、H2O等。

二、利用高能高臭氧UV紫外线光束分解空气中的氧分子产生游离氧,即活性氧,因游离氧所携正负电子不平衡所以需与氧分子结合,进而产生臭氧。

UV+O2→O-+O*(活性氧)O+O2→O3(臭氧),众所周知臭氧对有机物具有极强的氧化作用,对恶臭气体及其它刺激性异味有立竿见影的清除效果。

三、恶臭气体利用排风设备输入到本净化设备后,净化设备运用高能UV紫外线光束及臭氧对恶臭气体进行协同分解氧化反应,使恶臭气体物质其降解转化成低分子化合物、水和二氧化碳,再通过排风管道排出室外。

四、利用高能UV光束裂解恶臭气体中细菌的分子键,破坏细菌的核酸(DNA),再通过臭氧进行氧化反应,彻底达到脱臭及杀灭细菌的目的.

THY-EQ系列恶臭气体UV高效光解废气净化设备的性能优势

㈠、高效除恶臭:能高效去除挥发性有机物(VOC)、无机物、硫化氢、氨气、硫醇类等主要污染物,以及各种恶臭味,脱臭效率最高可达99%以上,脱臭效果大大超过国家1993年颁布的恶臭污染物排放标准(GB14554-93)和1996年颁布的《大气污染物综合排放标准》(GB16297-1996)。

㈡、无需添加任何物质:只需要设置相应的排风管道和排风动力,使恶臭/工业废气通过本设备进行脱臭分解净化,无需添加任何物质参与化学反应。

㈢、适应性强:THY-系列工业废气(工业废气)UV高效光解废气净化设备可适应高浓度,大气量,不同工业废气物质的脱臭、净化处理,可每天24小时连续工作,运行稳定可靠。

㈣、运行成本低:THY-系列工业废气(工业废气)UV高效光解废气净化设备无任何机械动作,无噪音,无需专人管理和日常维护,只需作定期检查,本设备能耗低,设备风阻极低<50pa,可节约大量排风动力能耗。

㈤、设备占地面积小,自重轻:适合于布置紧凑、场地狭小等特殊条件,设备占地面积<1平方米/处理10000m3/h风量。

㈥、优质进口材料制造:防火、防腐蚀性能高,设备性能安全稳定,采用不锈钢材质,设备使用寿命在十五年以上。

㈦、环保高科技专利产品:采用国际上最先进技术理念,通过专家及我公司工程技术人员长期反复的试验,开发研制出的,具有完全自主知识产权的高科技环保净化产品可彻底分解工业废气中有毒有害物质,并能达到完美的脱臭、净化效果,经分解后的工业废气,可完全达到无害化排放,不产生二次污染,同时达到高效消毒杀菌的作用。

㈧、防爆认证产品:设备具有安全、防爆特性,已通过国家防爆电器产品质量监督检验中心的Ex防爆合格认证(证书编号:CNEx13.0792 X),能广泛应用于采油(气)田、石油化工、制药等防爆要求高的行业。

uv光解氧化除臭设备 废气处理设备uv高效光解净化设备适用范围 :

炼油厂、橡胶厂、化工厂、制药厂、污水处理厂、垃圾转运站等恶臭气体的脱臭净化处理。

物质名称

恶臭气体主要来源

硫化氢

牛皮纸浆、炼油、炼焦、石化、煤气、粪便处理、二硫化碳的生产或加工

硫醇类

牛皮纸浆、炼油、煤气、制药、农药、合成树酯、合成纤维、橡胶

硫醚类

牛皮纸浆、炼油、农药、垃圾处理、生活污水下水道

氨

氮肥、硝酸、炼焦、粪便处理、肉类加工

胺类

水产加工,畜产加工、皮革、骨胶

吲哚类

粪便处理、生活污水处理、炼焦、肉类腐烂、屠宰牲畜

硝基

燃料、炸药

烃类

炼油、炼焦、石油化工、电石、化肥、内燃机排气、油漆、溶剂、油墨印刷

醛类

炼油、石油化工、医药、内燃机排气、垃圾处理、铸

Electronic factory waste gas treatment - fish meal factory exhaust gas treatment electroplating waste gas treatment - leather factory waste processing factory production, blue Yang environmental protection hotline: 0519-8166866213179310883, welcome to contact us! ~ ~

Acid gas purification tower:

I. overview:

Mist purification tower for waste gas treatment in sulfuric acid, nitric acid, hydrofluoric acid, hydrochloric acid and other processes produced in the process of acid gas. BST type mist purification tower is a tower packed type circular structure of gas-liquid mass transfer. The packing layer is two 25- Phi Phi 38 cascade ring, each main filler is 500 ~ 800mm. This equipment uses spray nozzle cloth. The water retaining plate is 90 degrees, 4 flaps. The treatment tower is composed of three parts: the lower part of a liquid tank section; the middle part of a filling spray and filling spray section; the upper section of a water retaining section. Purification tower with angle steel reinforced frame and maintenance ladder, a liquid pump solution circulation system. The absorption solution is generally 5 ~ 10%NaOH, when the treatment of nitric acid gas, it is recommended to add Na2S solution to improve the purification efficiency.

The equipment is not equipped with exhaust fan, but also can be purchased according to user requirements.

The utility model has the advantages of high purifying efficiency, compact structure, small occupation area, good corrosion resistance, aging resistance, light weight, convenient installation and transportation.

Equipment characteristics:

1. High adsorption rate, low amount of activated carbon fiber, low cost.

The adsorption and desorption of activated carbon fiber is fast, the adsorption time of each cycle is short, the loading quantity is small, the equipment is exquisite, the investment is low.

2. High recovery solvent quality

The adsorption and desorption time is short, the temperature is relatively high, does not promote the decomposition of organic matter, so the recovery of solvent can be directly recycled production.

3) low energy consumption and low cost.

The desorption and regeneration of activated carbon fiber is low, the airflow resistance of the winding core is small, the power of the fan is small, and the energy consumption of the equipment is low.

4) low cost to achieve high air volume treatment.

According to the operation of advanced technology patent for many years practical experience of evolution, can configure the number of at least a adsorber and achieve maximum waste gas treatment capacity, thereby reducing the cost, reduce the user area.

5. Safe and reliable, suitable for explosive hazardous sites.

Explosion-proof fan, explosion-proof pump. The control cabinet and the pneumatic cabinet adopt the positive pressure explosion-proof technology, the external signal is connected with the safety gate, and the system is grounded to ensure the safety of the device.

6. Not only can control pollution, but also the recovery of goods will produce economic benefits, short-term investment can be recovered.

UV photolysis oxidation deodorization equipment waste gas treatment equipment UV high efficiency photolysis purification equipment

First, using a special UV ultraviolet light irradiation of high-energy malodorous gases, such as ammonia, malodorous gas cracking trimethylamine, hydrogen sulfide, dimethyl sulfide hydrogen, methyl mercaptan and dimethyl sulfide, two methyl two sulfur, carbon disulfide and styrene, sulfide H2S, VOC, molecular bond of benzene and toluene and xylene.

Two, the use of high ozone decomposition of oxygen molecules in the air to produce oxygen free, active oxygen, free oxygen carried by the electron positron imbalance so the need to combine with oxygen molecules, and produce ozone, which is in the pollutant molecules and ozone oxidation free state with small molecular compounds into harmless or less harmful. Such as CO2, H2O, etc.. UV+O2 - O-+O* (reactive oxygen species) O+O2 - O3 (ozone).

The technical principle of UV photolysis oxidation deodorization equipment waste gas treatment equipment UV high efficiency photolysis purification equipment

A, the product with special high ozone UV ultraviolet beam irradiation of malodorous gases, malodorous gases such as ammonia, change of trimethylamine, hydrogen sulfide, dimethyl sulfide hydrogen, methyl mercaptan and dimethyl sulfide, two methyl two sulfur, carbon disulfide and styrene, sulfide H2S, VOC, molecular chain structure of benzene, toluene and xylene so, organic or inorganic polymer malodorous compounds molecular chain in high-energy ultraviolet light irradiation, the degradation into low molecular compounds, such as CO2, H2O etc..

Two, the use of high energy and high ozone UV ultraviolet beam decomposition of oxygen molecules in the air to produce free oxygen, that is, reactive oxygen species, due to the free oxygen brought by the positive and negative electron imbalance so the need to combine with oxygen molecules, and thus produce ozone.

UV + O2 ~ O-+O * (reactive oxygen species) O+O2 - O3 (ozone), as is known to all ozone has a strong oxidation of organic matter, odor gases and other irritating odor has an immediate effect of removal.

Three, the use of foul gas exhaust equipment into the purification equipment, purification equipment using high energy UV light beam and the odor of ozone decomposition CO oxidation reaction of the malodorous gases into the material degradation of low molecular compounds, water and carbon dioxide, and then exhausted to the outside through the exhaust pipe.

Four, the use of high energy UV beam cracking of bacteria in the odor of molecular bonds, the destruction of the bacterial nucleic acid (DNA), and then through the ozone oxidation reaction, to achieve the purpose of deodorization and killing bacteria

The performance advantages of THY-EQ series of high performance UV gas purification equipment

In addition, a high efficient odor removal of volatile organic compounds (VOC), the main pollutants of inorganic compounds, ammonia, hydrogen sulfide, mercaptans, and odor, deodorization efficiency up to 99% or more, the deodorization effect greatly exceeded the national emission standard of odor pollutants issued in 1993 (GB14554-93) and 1996 promulgated the "comprehensive air pollutant emission standards" (GB16297-1996).

Two, no need to add any substance: only need to set up the corresponding exhaust pipe and exhaust power, so that the stench / industrial waste gas through the equipment deodorization decomposition and purification, no need to add any substance to participate in chemical reactions.

Three, strong adaptability

酸气净化塔:

一、概述:

酸雾净化塔适用于硫酸、硝酸、氢氟酸、盐酸等工艺操作过程中产生酸性气体的废气治理。BST型酸雾净化塔是一种填料式气液传质园形结构的处理塔。填料层为二级φ25-φ38聚丙烯阶梯环,每级填料主为500~800mm。本设备采用喷嘴雾布液。挡水板为90°、4折板。处理塔由三个部分组成:下段一液箱段;中段一填料喷淋再填料喷淋段;上段一挡水段。净化塔设有角钢加固框架和检修梯,设有液下泵等溶液循环系统。吸收液一般采用5~10%NaOH,当处理硝酸气体时,建议加Na2S溶液以提高净化效率。

本设备不配带带排风机,但亦可按用户要求代购。

本设备具有净化效率高、结构紧凑,占地面积小、耐腐蚀、耐老化性能好,重量轻,便于安装、运输。

设备特点:

1).吸附率高,活性炭纤维用量少,造价低。

活性炭纤维吸附、脱附速度快,每一次循环的吸附时间短,装填量小,设备精巧,投资低。

2).回收溶剂品质高

吸附和解吸的时间短,温度相对不高,不促使有机物分解,因此回收溶剂可直接回用生产。

3).运行能耗低、费用低。

活性炭纤维的脱附、再生能耗低,缠绕芯的气流阻力小、风机功率小,设备耗能低。

4).低成本实现大风量处理。

根据多年实践经验总结进化的先进运行工艺专利技术,能够配置最少的吸附器个数而达到最大的废气处理能力,从而降低了造价、减少了用户的占地面积。

5).安全可靠、适用于有爆炸危险场所。

采用防爆风机、防爆泵。控制柜、气动柜采用正压防爆技术,外部信号通过安全栅连接,系统接地,确保了装置的安全性。

6).不仅可以治理污染,而且回收的物品会产生经济效益,短期内即可收回投资。

uv光解氧化除臭设备 废气处理设备uv高效光解净化设备

一、利用特制的高能UV紫外线光束照射恶臭气体,裂解恶臭气体如:氨、三甲胺、硫化氢、甲硫氢、甲硫醇、甲硫醚、二甲二硫、二硫化碳和苯乙烯,硫化物H2S、VOC类,苯、甲苯、二甲苯的分子键。

二、利用高臭氧分解空气中的氧分子产生游离氧,即活性氧,因游离氧所携正负电子不平衡所以需与氧分子结合,进而产生臭氧,使呈游离状态的污染物分子与臭氧氧化结合成小分子无害或低害的化合物。如CO2、H2O等。UV+O2→O-+O*(活性氧)O+O2→O3(臭氧)。

uv光解氧化除臭设备 废气处理设备uv高效光解净化设备技术原理

一、本产品利用特制的高能高臭氧UV紫外线光束照射恶臭气体,改变恶臭气体如:氨、三甲胺、硫化氢、甲硫氢、甲硫醇、甲硫醚、二甲二硫、二硫化碳和苯乙烯,硫化物H2S、VOC类,苯、甲苯、二甲苯的分子链结构,使有机或无机高分子恶臭化合物分子链,在高能紫外线光束照射下,降解转变成低分子化合物,如CO2、H2O等。

二、利用高能高臭氧UV紫外线光束分解空气中的氧分子产生游离氧,即活性氧,因游离氧所携正负电子不平衡所以需与氧分子结合,进而产生臭氧。

UV+O2→O-+O*(活性氧)O+O2→O3(臭氧),众所周知臭氧对有机物具有极强的氧化作用,对恶臭气体及其它刺激性异味有立竿见影的清除效果。

三、恶臭气体利用排风设备输入到本净化设备后,净化设备运用高能UV紫外线光束及臭氧对恶臭气体进行协同分解氧化反应,使恶臭气体物质其降解转化成低分子化合物、水和二氧化碳,再通过排风管道排出室外。

四、利用高能UV光束裂解恶臭气体中细菌的分子键,破坏细菌的核酸(DNA),再通过臭氧进行氧化反应,彻底达到脱臭及杀灭细菌的目的.

THY-EQ系列恶臭气体UV高效光解废气净化设备的性能优势

㈠、高效除恶臭:能高效去除挥发性有机物(VOC)、无机物、硫化氢、氨气、硫醇类等主要污染物,以及各种恶臭味,脱臭效率最高可达99%以上,脱臭效果大大超过国家1993年颁布的恶臭污染物排放标准(GB14554-93)和1996年颁布的《大气污染物综合排放标准》(GB16297-1996)。

㈡、无需添加任何物质:只需要设置相应的排风管道和排风动力,使恶臭/工业废气通过本设备进行脱臭分解净化,无需添加任何物质参与化学反应。

㈢、适应性强:THY-系列工业废气(工业废气)UV高效光解废气净化设备可适应高浓度,大气量,不同工业废气物质的脱臭、净化处理,可每天24小时连续工作,运行稳定可靠。

㈣、运行成本低:THY-系列工业废气(工业废气)UV高效光解废气净化设备无任何机械动作,无噪音,无需专人管理和日常维护,只需作定期检查,本设备能耗低,设备风阻极低<50pa,可节约大量排风动力能耗。

㈤、设备占地面积小,自重轻:适合于布置紧凑、场地狭小等特殊条件,设备占地面积<1平方米/处理10000m3/h风量。

㈥、优质进口材料制造:防火、防腐蚀性能高,设备性能安全稳定,采用不锈钢材质,设备使用寿命在十五年以上。

㈦、环保高科技专利产品:采用国际上最先进技术理念,通过专家及我公司工程技术人员长期反复的试验,开发研制出的,具有完全自主知识产权的高科技环保净化产品可彻底分解工业废气中有毒有害物质,并能达到完美的脱臭、净化效果,经分解后的工业废气,可完全达到无害化排放,不产生二次污染,同时达到高效消毒杀菌的作用。

㈧、防爆认证产品:设备具有安全、防爆特性,已通过国家防爆电器产品质量监督检验中心的Ex防爆合格认证(证书编号:CNEx13.0792 X),能广泛应用于采油(气)田、石油化工、制药等防爆要求高的行业。

uv光解氧化除臭设备 废气处理设备uv高效光解净化设备适用范围 :

炼油厂、橡胶厂、化工厂、制药厂、污水处理厂、垃圾转运站等恶臭气体的脱臭净化处理。

物质名称

恶臭气体主要来源

硫化氢

牛皮纸浆、炼油、炼焦、石化、煤气、粪便处理、二硫化碳的生产或加工

硫醇类

牛皮纸浆、炼油、煤气、制药、农药、合成树酯、合成纤维、橡胶

硫醚类

牛皮纸浆、炼油、农药、垃圾处理、生活污水下水道

氨

氮肥、硝酸、炼焦、粪便处理、肉类加工

胺类

水产加工,畜产加工、皮革、骨胶

吲哚类

粪便处理、生活污水处理、炼焦、肉类腐烂、屠宰牲畜

硝基

燃料、炸药

烃类

炼油、炼焦、石油化工、电石、化肥、内燃机排气、油漆、溶剂、油墨印刷

醛类

炼油、石油化工、医药、内燃机排气、垃圾处理、铸

Electronic factory waste gas treatment - fish meal factory exhaust gas treatment electroplating waste gas treatment - leather factory waste processing factory production, blue Yang environmental protection hotline: 0519-8166866213179310883, welcome to contact us! ~ ~

Acid gas purification tower:

I. overview:

Mist purification tower for waste gas treatment in sulfuric acid, nitric acid, hydrofluoric acid, hydrochloric acid and other processes produced in the process of acid gas. BST type mist purification tower is a tower packed type circular structure of gas-liquid mass transfer. The packing layer is two 25- Phi Phi 38 cascade ring, each main filler is 500 ~ 800mm. This equipment uses spray nozzle cloth. The water retaining plate is 90 degrees, 4 flaps. The treatment tower is composed of three parts: the lower part of a liquid tank section; the middle part of a filling spray and filling spray section; the upper section of a water retaining section. Purification tower with angle steel reinforced frame and maintenance ladder, a liquid pump solution circulation system. The absorption solution is generally 5 ~ 10%NaOH, when the treatment of nitric acid gas, it is recommended to add Na2S solution to improve the purification efficiency.

The equipment is not equipped with exhaust fan, but also can be purchased according to user requirements.

The utility model has the advantages of high purifying efficiency, compact structure, small occupation area, good corrosion resistance, aging resistance, light weight, convenient installation and transportation.

Equipment characteristics:

1. High adsorption rate, low amount of activated carbon fiber, low cost.

The adsorption and desorption of activated carbon fiber is fast, the adsorption time of each cycle is short, the loading quantity is small, the equipment is exquisite, the investment is low.

2. High recovery solvent quality

The adsorption and desorption time is short, the temperature is relatively high, does not promote the decomposition of organic matter, so the recovery of solvent can be directly recycled production.

3) low energy consumption and low cost.

The desorption and regeneration of activated carbon fiber is low, the airflow resistance of the winding core is small, the power of the fan is small, and the energy consumption of the equipment is low.

4) low cost to achieve high air volume treatment.

According to the operation of advanced technology patent for many years practical experience of evolution, can configure the number of at least a adsorber and achieve maximum waste gas treatment capacity, thereby reducing the cost, reduce the user area.

5. Safe and reliable, suitable for explosive hazardous sites.

Explosion-proof fan, explosion-proof pump. The control cabinet and the pneumatic cabinet adopt the positive pressure explosion-proof technology, the external signal is connected with the safety gate, and the system is grounded to ensure the safety of the device.

6. Not only can control pollution, but also the recovery of goods will produce economic benefits, short-term investment can be recovered.

UV photolysis oxidation deodorization equipment waste gas treatment equipment UV high efficiency photolysis purification equipment

First, using a special UV ultraviolet light irradiation of high-energy malodorous gases, such as ammonia, malodorous gas cracking trimethylamine, hydrogen sulfide, dimethyl sulfide hydrogen, methyl mercaptan and dimethyl sulfide, two methyl two sulfur, carbon disulfide and styrene, sulfide H2S, VOC, molecular bond of benzene and toluene and xylene.

Two, the use of high ozone decomposition of oxygen molecules in the air to produce oxygen free, active oxygen, free oxygen carried by the electron positron imbalance so the need to combine with oxygen molecules, and produce ozone, which is in the pollutant molecules and ozone oxidation free state with small molecular compounds into harmless or less harmful. Such as CO2, H2O, etc.. UV+O2 - O-+O* (reactive oxygen species) O+O2 - O3 (ozone).

The technical principle of UV photolysis oxidation deodorization equipment waste gas treatment equipment UV high efficiency photolysis purification equipment

A, the product with special high ozone UV ultraviolet beam irradiation of malodorous gases, malodorous gases such as ammonia, change of trimethylamine, hydrogen sulfide, dimethyl sulfide hydrogen, methyl mercaptan and dimethyl sulfide, two methyl two sulfur, carbon disulfide and styrene, sulfide H2S, VOC, molecular chain structure of benzene, toluene and xylene so, organic or inorganic polymer malodorous compounds molecular chain in high-energy ultraviolet light irradiation, the degradation into low molecular compounds, such as CO2, H2O etc..

Two, the use of high energy and high ozone UV ultraviolet beam decomposition of oxygen molecules in the air to produce free oxygen, that is, reactive oxygen species, due to the free oxygen brought by the positive and negative electron imbalance so the need to combine with oxygen molecules, and thus produce ozone.

UV + O2 ~ O-+O * (reactive oxygen species) O+O2 - O3 (ozone), as is known to all ozone has a strong oxidation of organic matter, odor gases and other irritating odor has an immediate effect of removal.

Three, the use of foul gas exhaust equipment into the purification equipment, purification equipment using high energy UV light beam and the odor of ozone decomposition CO oxidation reaction of the malodorous gases into the material degradation of low molecular compounds, water and carbon dioxide, and then exhausted to the outside through the exhaust pipe.

Four, the use of high energy UV beam cracking of bacteria in the odor of molecular bonds, the destruction of the bacterial nucleic acid (DNA), and then through the ozone oxidation reaction, to achieve the purpose of deodorization and killing bacteria

The performance advantages of THY-EQ series of high performance UV gas purification equipment

In addition, a high efficient odor removal of volatile organic compounds (VOC), the main pollutants of inorganic compounds, ammonia, hydrogen sulfide, mercaptans, and odor, deodorization efficiency up to 99% or more, the deodorization effect greatly exceeded the national emission standard of odor pollutants issued in 1993 (GB14554-93) and 1996 promulgated the "comprehensive air pollutant emission standards" (GB16297-1996).

Two, no need to add any substance: only need to set up the corresponding exhaust pipe and exhaust power, so that the stench / industrial waste gas through the equipment deodorization decomposition and purification, no need to add any substance to participate in chemical reactions.

Three, strong adaptability

相关产品推荐

-

湖州废气处理_湖州工业废气处理_湖州活性炭吸附塔 厂家定制

湖州废气处理_湖州工业废气处理_湖州活性炭吸附塔 厂家定制

-

南京废气处理,徐州废气处理,苏州废气处理 加工定制

南京废气处理,徐州废气处理,苏州废气处理 加工定制

-

印刷厂废气处理-制药厂废气处理-喷涂厂废气处理-化工厂废气处理-喷漆厂废气处理

印刷厂废气处理-制药厂废气处理-喷涂厂废气处理-化工厂废气处理-喷漆厂废气处理

-

UV光解氧化设备/UV光解废气处理/uv光解除臭设备/uv光催化氧化设备 供应厂家

UV光解氧化设备/UV光解废气处理/uv光解除臭设备/uv光催化氧化设备 供应厂家

-

有机废气净化、废气净化设备、废气净化工程、废气净化装置 环保达标

有机废气净化、废气净化设备、废气净化工程、废气净化装置 环保达标

-

玻璃钢净化塔\玻璃钢酸雾塔\玻璃钢废气塔\玻璃钢填料塔\玻璃钢废气吸收塔

玻璃钢净化塔\玻璃钢酸雾塔\玻璃钢废气塔\玻璃钢填料塔\玻璃钢废气吸收塔

-

农药厂废气处理\橡胶厂废气处理\家具厂废气处理\污水厂废气处理\冶炼厂废气处理

农药厂废气处理\橡胶厂废气处理\家具厂废气处理\污水厂废气处理\冶炼厂废气处理

-

活性炭吸附装置-活性炭吸附设备-填料塔-玻璃钢废气处理塔-专业厂家

活性炭吸附装置-活性炭吸附设备-填料塔-玻璃钢废气处理塔-专业厂家

-

有机废气净化塔,有机废气处理塔,喷漆废气净化塔,盐酸废气净化塔 加工定制

有机废气净化塔,有机废气处理塔,喷漆废气净化塔,盐酸废气净化塔 加工定制

-

专注于聚丙烯废气吸收塔-吸附塔-不锈钢废气塔-不锈钢废气处理塔

专注于聚丙烯废气吸收塔-吸附塔-不锈钢废气塔-不锈钢废气处理塔