厂商 :常州蓝阳环保设备有限公司

江苏 常州- 主营产品:

- 活性炭吸附箱

- 废气处理设备

- 废气净化设备

联系电话 :13179310883

商品详细描述

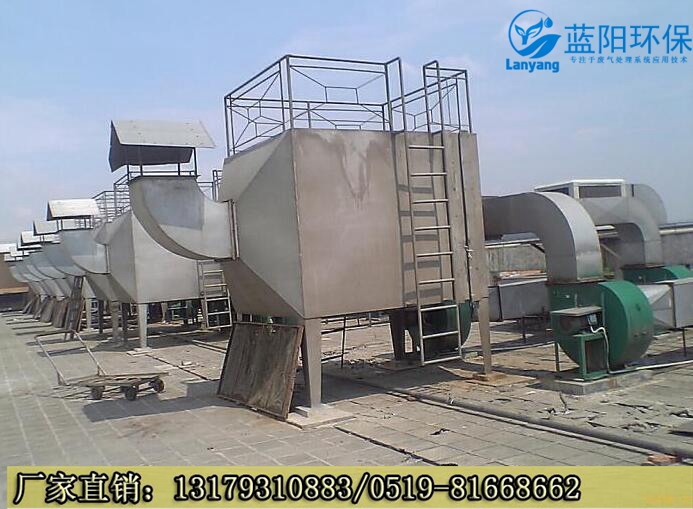

印刷厂废气处理-制药厂废气处理-喷涂厂废气处理-化工厂废气处理-喷漆厂废气处理,蓝阳环保,咨询热线:0519-81668662,13179310883,欢迎您的来电垂询!~~

适用范围:

适用于低浓度大风量或高浓度间歇排放废气的作业环境。电子原件生产、电池生产、酸洗作业、实验室排风、冶金、化工、医药、涂装、轻工、橡胶、船舶、汽车、石油、喷漆、酿造及家具生产等行业废气净化。

工作原理:

车间含有有机气体或颗粒物经获罩收集,管道输送有机气体进入活性炭塔,有机气体进入塔内时,风速顺间降下,气体内含的较大颗粒杂物便自然沉降入塔底部,而溶入气体内的有机气体部分随气体流向流进活性炭过滤层,有机气体进入炭层时,有机气体被活性炭吸附进炭内,而干尽的空气穿过炭层进入出气仓,气体经过机械自吸后排入大气中.而活性炭层的在吸附过程中,炭会有个饱和的时间段,其活性炭饱和的过程长短与气体本身内部所含气体的浓度和工作的时间长短有直接相关。

活性炭吸附箱是一种干式废气处理设备。由箱体和装填在箱体内的吸附单元组成。根据吸附单元的数量和风量共分为多种规格,活性炭吸附箱选择不同填料可以处理多种不同废气,主要包括叁大类:

1,酸性废气和酸雾

2,碱性废气

3,有机废气和臭味(苯类、酚类、醇类、醚类、酊类)

活性炭吸附箱对于浓度低于1000mg/m<sup>3</sup>的废气净化后排放满足

有机废气的处理方法种类繁多,特点各异,常用的有冷凝法、吸收法、燃烧法、催化法、吸附法等。

1、冷凝回收法:将废气直接冷凝或吸附浓缩后冷凝,冷凝液经分离回收有价值的有机物。该法用于浓度高、温度低、风量小的废气处理。但此法投资大、能耗高、运行费用大,因此无特殊需要,一般不采用此法。

2、吸收法:可分为化学吸收和物理吸收,但“三苯”废气化学活性低,一般不采用化学吸收。物理吸收是选用具有较小的挥发性的液体吸收剂,它与被吸收组分有较高的亲和力,吸收饱和后经加热解析冷却后重新使用。该法用于大气量、温度低、浓度低的废气。装置复杂、投资大,吸收液的选用比较困难,存在二次污染。

3、直接燃烧法:利用燃气或燃油等辅助燃料燃烧放出的热量将混合气体加热到一定温度(700—800℃),驻留一定的时间,使可燃的有害气体燃烧。该法工艺简单、设备投资少,但能耗大、运行成本高。

4、催化燃烧法:将废气加热到200~300℃经过催化床燃烧,达到净化目的。该法能耗低、净化率高、无二次污染、工艺简单操作方便。

适用于高温高浓度的有机废气治理,不适用于低浓度、大风量的有机废气治理。

常州蓝阳环保设备有限公司是国内较早从事并拥用自主知识产权的工业有机废气(VOCs)治理的专业厂家,先后在活性碳纤维吸附材料及装备、蓄热氧化处理工艺及装备、分子筛吸附浓缩转轮技术等领域取得突破,掌握多项世界先进水平的核心技术和产品工艺。公司产品广泛应用于汽车涂装、石油化工、包装印刷、医药制造、涂布涂料等VOCs治理行业,对于大风量、低浓度、成分复杂的各类工业有机废气,通过组合工艺设计,达到处理效率高、能源消耗低、运行费用低、安全可靠的效果;其中蓄热氧化装置(RTO)、分子筛吸附浓缩转轮、纳米纤维除尘滤筒、ACF吸附回收等环保设备性能优良.

Printing plant waste gas treatment - pharmaceutical plant waste gas treatment - spraying plant waste gas treatment - chemical plant waste gas treatment - paint factory waste gas treatment, blue Yang environmental protection, Consulting Hotline: 0519-8166866213179310883, welcome your call! ~ ~

Application scope:

The utility model is suitable for the working environment of intermittent exhaust gas with low concentration and large air volume or high concentration. Electronic components production, battery production, pickling, laboratory ventilation, metallurgy and chemical industry, light industry, medicine, coating, rubber, shipbuilding, automobile, oil, paint, brewing and furniture production industry waste gas purification.

Working principle:

The workshop contains organic gases or particles by a cover collection, pipeline transport of organic gases into the activated carbon tower, organic gas into the tower, the wind Shun down, large particle debris containing natural gas into the settlement at the bottom of the tower, and the organic gas into gas in part with the gas flow into the active carbon filter layer, organic gas enters into the carbon layer, organic gases by activated carbon adsorption in carbon, and do the air through the charcoal layer into the outlet chamber, gas is discharged into atmosphere through mechanical self absorption. And the active carbon layer in the adsorption process, carbon saturation will have a period of time, are directly related to the length of time of its activity carbon saturated process and gas itself contained gas concentration and work.

Activated carbon adsorption tank is a dry waste gas treatment equipment. The utility model is composed of a box body and an adsorption unit which is arranged in the box body. According to the number of adsorption units and air volume is divided into a variety of specifications, activated carbon adsorption tank to choose a variety of different types of waste gas can be treated, including three categories:

1, acid gas and acid mist

2, alkaline waste gas

3, the organic waste gas and odor (benzene, phenols, alcohols, ethers, tincture of class)

Activated carbon adsorption tank for the concentration of less than 1000mg/m<sup>3</sup> after the purification of exhaust emissions meet

There are many kinds of treatment methods of organic waste gas, which are characterized by condensation, absorption, combustion, catalysis, adsorption and so on.

1, condensation recovery method: the direct condensation of waste gas or adsorption condensation condensation, condensate separation and recovery of valuable organic matter. The method is used for the treatment of high concentration, low temperature and small air volume. But this method of large investment, high energy consumption, high operating costs, and therefore no special needs, generally do not use this method.

2, absorption method: can be divided into chemical absorption and physical absorption, but "three benzene" waste gas chemical activity is low, generally do not use chemical absorption. Physical absorption is to choose a smaller volatile liquid absorbent, it has a higher affinity with the absorbed component, after the absorption of saturated cooling after heating analysis to re-use. The method is used for the atmospheric, low temperature, low concentration of exhaust gas. The device is complex, the investment is large, the selection of the absorption liquid is difficult, there are two pollution.

3, direct combustion method: the use of gas or fuel and other auxiliary fuel combustion emissions of heat will be mixed gas heating to a certain temperature (700 - 800 C), stay a certain time, so that the combustion of harmful gases. This method has the advantages of simple process, less equipment investment, high energy consumption and high operation cost.

4, catalytic combustion method: the exhaust gas heated to 200~300 DEG C after catalytic bed combustion, to achieve the purpose of purification. The method has the advantages of low energy consumption, high purification rate, no two pollution, simple process and convenient operation.

Suitable for high temperature and high concentration of organic waste gas treatment, not suitable for low concentration, large volume of organic waste gas treatment.

Changzhou blue Yang environmental protection equipment Co. Ltd is engaged in the earlier and have independent intellectual property rights of industrial organic waste gas (VOCs) governance of professional manufacturers, has in the adsorption of active carbon fiber materials and equipment, the regenerative oxidation treatment process and equipment, molecular sieve adsorption concentration runner technology breakthrough, grasp the core technology and product technology a number of the world's advanced level. Our products are widely used in automobile, petroleum and chemical industry, pharmaceutical manufacturing, packaging and printing, coating and other industries for VOCs governance, large flow and low concentration and complex composition of all kinds of industrial organic waste gas, through a combination of process design, to achieve high efficiency, low energy consumption, low operation cost, safe and reliable effect among them; the regenerative oxidation device (RTO), molecular sieve adsorption concentration runner, nano fiber dust filter, ACF adsorption recycling and excellent environmental protection equipment performance

适用范围:

适用于低浓度大风量或高浓度间歇排放废气的作业环境。电子原件生产、电池生产、酸洗作业、实验室排风、冶金、化工、医药、涂装、轻工、橡胶、船舶、汽车、石油、喷漆、酿造及家具生产等行业废气净化。

工作原理:

车间含有有机气体或颗粒物经获罩收集,管道输送有机气体进入活性炭塔,有机气体进入塔内时,风速顺间降下,气体内含的较大颗粒杂物便自然沉降入塔底部,而溶入气体内的有机气体部分随气体流向流进活性炭过滤层,有机气体进入炭层时,有机气体被活性炭吸附进炭内,而干尽的空气穿过炭层进入出气仓,气体经过机械自吸后排入大气中.而活性炭层的在吸附过程中,炭会有个饱和的时间段,其活性炭饱和的过程长短与气体本身内部所含气体的浓度和工作的时间长短有直接相关。

活性炭吸附箱是一种干式废气处理设备。由箱体和装填在箱体内的吸附单元组成。根据吸附单元的数量和风量共分为多种规格,活性炭吸附箱选择不同填料可以处理多种不同废气,主要包括叁大类:

1,酸性废气和酸雾

2,碱性废气

3,有机废气和臭味(苯类、酚类、醇类、醚类、酊类)

活性炭吸附箱对于浓度低于1000mg/m<sup>3</sup>的废气净化后排放满足

有机废气的处理方法种类繁多,特点各异,常用的有冷凝法、吸收法、燃烧法、催化法、吸附法等。

1、冷凝回收法:将废气直接冷凝或吸附浓缩后冷凝,冷凝液经分离回收有价值的有机物。该法用于浓度高、温度低、风量小的废气处理。但此法投资大、能耗高、运行费用大,因此无特殊需要,一般不采用此法。

2、吸收法:可分为化学吸收和物理吸收,但“三苯”废气化学活性低,一般不采用化学吸收。物理吸收是选用具有较小的挥发性的液体吸收剂,它与被吸收组分有较高的亲和力,吸收饱和后经加热解析冷却后重新使用。该法用于大气量、温度低、浓度低的废气。装置复杂、投资大,吸收液的选用比较困难,存在二次污染。

3、直接燃烧法:利用燃气或燃油等辅助燃料燃烧放出的热量将混合气体加热到一定温度(700—800℃),驻留一定的时间,使可燃的有害气体燃烧。该法工艺简单、设备投资少,但能耗大、运行成本高。

4、催化燃烧法:将废气加热到200~300℃经过催化床燃烧,达到净化目的。该法能耗低、净化率高、无二次污染、工艺简单操作方便。

适用于高温高浓度的有机废气治理,不适用于低浓度、大风量的有机废气治理。

常州蓝阳环保设备有限公司是国内较早从事并拥用自主知识产权的工业有机废气(VOCs)治理的专业厂家,先后在活性碳纤维吸附材料及装备、蓄热氧化处理工艺及装备、分子筛吸附浓缩转轮技术等领域取得突破,掌握多项世界先进水平的核心技术和产品工艺。公司产品广泛应用于汽车涂装、石油化工、包装印刷、医药制造、涂布涂料等VOCs治理行业,对于大风量、低浓度、成分复杂的各类工业有机废气,通过组合工艺设计,达到处理效率高、能源消耗低、运行费用低、安全可靠的效果;其中蓄热氧化装置(RTO)、分子筛吸附浓缩转轮、纳米纤维除尘滤筒、ACF吸附回收等环保设备性能优良.

Printing plant waste gas treatment - pharmaceutical plant waste gas treatment - spraying plant waste gas treatment - chemical plant waste gas treatment - paint factory waste gas treatment, blue Yang environmental protection, Consulting Hotline: 0519-8166866213179310883, welcome your call! ~ ~

Application scope:

The utility model is suitable for the working environment of intermittent exhaust gas with low concentration and large air volume or high concentration. Electronic components production, battery production, pickling, laboratory ventilation, metallurgy and chemical industry, light industry, medicine, coating, rubber, shipbuilding, automobile, oil, paint, brewing and furniture production industry waste gas purification.

Working principle:

The workshop contains organic gases or particles by a cover collection, pipeline transport of organic gases into the activated carbon tower, organic gas into the tower, the wind Shun down, large particle debris containing natural gas into the settlement at the bottom of the tower, and the organic gas into gas in part with the gas flow into the active carbon filter layer, organic gas enters into the carbon layer, organic gases by activated carbon adsorption in carbon, and do the air through the charcoal layer into the outlet chamber, gas is discharged into atmosphere through mechanical self absorption. And the active carbon layer in the adsorption process, carbon saturation will have a period of time, are directly related to the length of time of its activity carbon saturated process and gas itself contained gas concentration and work.

Activated carbon adsorption tank is a dry waste gas treatment equipment. The utility model is composed of a box body and an adsorption unit which is arranged in the box body. According to the number of adsorption units and air volume is divided into a variety of specifications, activated carbon adsorption tank to choose a variety of different types of waste gas can be treated, including three categories:

1, acid gas and acid mist

2, alkaline waste gas

3, the organic waste gas and odor (benzene, phenols, alcohols, ethers, tincture of class)

Activated carbon adsorption tank for the concentration of less than 1000mg/m<sup>3</sup> after the purification of exhaust emissions meet

There are many kinds of treatment methods of organic waste gas, which are characterized by condensation, absorption, combustion, catalysis, adsorption and so on.

1, condensation recovery method: the direct condensation of waste gas or adsorption condensation condensation, condensate separation and recovery of valuable organic matter. The method is used for the treatment of high concentration, low temperature and small air volume. But this method of large investment, high energy consumption, high operating costs, and therefore no special needs, generally do not use this method.

2, absorption method: can be divided into chemical absorption and physical absorption, but "three benzene" waste gas chemical activity is low, generally do not use chemical absorption. Physical absorption is to choose a smaller volatile liquid absorbent, it has a higher affinity with the absorbed component, after the absorption of saturated cooling after heating analysis to re-use. The method is used for the atmospheric, low temperature, low concentration of exhaust gas. The device is complex, the investment is large, the selection of the absorption liquid is difficult, there are two pollution.

3, direct combustion method: the use of gas or fuel and other auxiliary fuel combustion emissions of heat will be mixed gas heating to a certain temperature (700 - 800 C), stay a certain time, so that the combustion of harmful gases. This method has the advantages of simple process, less equipment investment, high energy consumption and high operation cost.

4, catalytic combustion method: the exhaust gas heated to 200~300 DEG C after catalytic bed combustion, to achieve the purpose of purification. The method has the advantages of low energy consumption, high purification rate, no two pollution, simple process and convenient operation.

Suitable for high temperature and high concentration of organic waste gas treatment, not suitable for low concentration, large volume of organic waste gas treatment.

Changzhou blue Yang environmental protection equipment Co. Ltd is engaged in the earlier and have independent intellectual property rights of industrial organic waste gas (VOCs) governance of professional manufacturers, has in the adsorption of active carbon fiber materials and equipment, the regenerative oxidation treatment process and equipment, molecular sieve adsorption concentration runner technology breakthrough, grasp the core technology and product technology a number of the world's advanced level. Our products are widely used in automobile, petroleum and chemical industry, pharmaceutical manufacturing, packaging and printing, coating and other industries for VOCs governance, large flow and low concentration and complex composition of all kinds of industrial organic waste gas, through a combination of process design, to achieve high efficiency, low energy consumption, low operation cost, safe and reliable effect among them; the regenerative oxidation device (RTO), molecular sieve adsorption concentration runner, nano fiber dust filter, ACF adsorption recycling and excellent environmental protection equipment performance

相关产品推荐

-

湖州废气处理_湖州工业废气处理_湖州活性炭吸附塔 厂家定制

湖州废气处理_湖州工业废气处理_湖州活性炭吸附塔 厂家定制

-

南京废气处理,徐州废气处理,苏州废气处理 加工定制

南京废气处理,徐州废气处理,苏州废气处理 加工定制

-

农药厂废气处理\橡胶厂废气处理\家具厂废气处理\污水厂废气处理\冶炼厂废气处理

农药厂废气处理\橡胶厂废气处理\家具厂废气处理\污水厂废气处理\冶炼厂废气处理

-

有机废气净化、废气净化设备、废气净化工程、废气净化装置 环保达标

有机废气净化、废气净化设备、废气净化工程、废气净化装置 环保达标

-

电子厂废气处理-鱼粉厂废气处理-电镀厂废气处理-皮革厂废气处理 厂家生产

电子厂废气处理-鱼粉厂废气处理-电镀厂废气处理-皮革厂废气处理 厂家生产

-

玻璃钢净化塔\玻璃钢酸雾塔\玻璃钢废气塔\玻璃钢填料塔\玻璃钢废气吸收塔

玻璃钢净化塔\玻璃钢酸雾塔\玻璃钢废气塔\玻璃钢填料塔\玻璃钢废气吸收塔

-

UV光解氧化设备/UV光解废气处理/uv光解除臭设备/uv光催化氧化设备 供应厂家

UV光解氧化设备/UV光解废气处理/uv光解除臭设备/uv光催化氧化设备 供应厂家

-

活性炭吸附装置-活性炭吸附设备-填料塔-玻璃钢废气处理塔-专业厂家

活性炭吸附装置-活性炭吸附设备-填料塔-玻璃钢废气处理塔-专业厂家

-

有机废气净化塔,有机废气处理塔,喷漆废气净化塔,盐酸废气净化塔 加工定制

有机废气净化塔,有机废气处理塔,喷漆废气净化塔,盐酸废气净化塔 加工定制

-

专注于聚丙烯废气吸收塔-吸附塔-不锈钢废气塔-不锈钢废气处理塔

专注于聚丙烯废气吸收塔-吸附塔-不锈钢废气塔-不锈钢废气处理塔