厂商 :常州蓝阳环保设备有限公司

江苏 常州- 主营产品:

- 活性炭吸附箱

- 废气处理设备

- 废气净化设备

联系电话 :13179310883

商品详细描述

玻璃钢净化塔\玻璃钢酸雾塔\玻璃钢废气塔\玻璃钢填料塔\玻璃钢废气吸收塔,蓝阳环保,咨询热线:0519-81668662,13179310883,欢迎您的来电垂询!~

技术执行标准:

(1)《中华人民共和国环境保护法》;

(2)《大气污染物综合排放标准》(GB16297-1996);

(3)《恶臭污染物排放标准》(GB14554-1993);

(4)《环境空气质量标准》(GB3095-1996);

(5)《工厂企业厂界噪声标准及其测量方法》(GB12348~12349-90);

(6)《工作场所有害因素职业接触限值》(GBZ 2-2002);

(7)《工业企业设计卫生标准》(GBZ 1-2002);

(8)《建设项目环境保护条例》中华人民共和国国务院令第253号 1998;

(9) 无刺激性异味排放;

设备构成及工作原理

1、构 成

酸雾吸收器由酸雾进酸系统、加水系统、吸收系统、排放系统四大部分组成。它与现场储酸槽连接组成一个闭环酸雾吸收系统。

2、工作原理

酸雾吸收器的酸雾进口与储酸槽的排气口用耐腐蚀管道连接成密闭系统,从加水口加入水并通过加水系统进行水喷淋,均匀喷洒下来,经过吸收系统让酸雾充分被水吸收后释放,然后水溶液通过排水口排出,去到中和池。

安装条件

(1) 室内应具备动力水源,水管管径DN≥20mm,常规动力水压应为0.2~0.4Mpa;

(2) 设备工作间地面应铺设耐酸瓷砖,并设有冲洗用水源和排水沟;

(3) 客户自备的储酸槽应具备一定的防护措施,如护栏、护墙、以及防泄露等装置。

YL型酸雾净化塔又可称为酸雾吸收塔,主要应用于各种化工、电工电子、冶金、工业生产等多种领域的气体净化。本型号设备主要是采用喷淋填料及气液交换塔盘净化工艺处理有害气体、处理的有害气体包括盐酸雾、硫酸雾、铬酸雾、硝酸雾、磷酸雾、氢氟酸雾、氯化氢、硫化氢、氰化氢等。

工作原理

本设备采用氢氧化钠溶液为吸收中和剂来净化废气。其工作流程是有害气体利用离心风机的动力被压入或吸入进风段,再向上流动至第一填料层与第一级喷嘴喷出的中和吸收液接触反应、被初级吸收后的废气继续向上与第二级喷嘴喷出的中和吸收液再次发生中和反应,根据具体废气数据可以加装第三极填料喷淋段以满足净化要求。

结构及特点

本净化塔可根据用户使用环境提供玻璃钢整体缠绕或PP塑料焊接两种材质的圆形塔体,设备无分段连接法兰有效的降低了设备漏风率及连接螺栓的腐坏率。具体结构有储液箱、进风段、填料层、喷淋段、脱水除沫装置、排气口组成。

其特点是:制作工艺先进、外形美观、安装检修方便且主体强度高、占地面积小、使用寿命长(三年以上)、设计制造灵活(可根据用户的废气数据确定喷淋填料层数)。

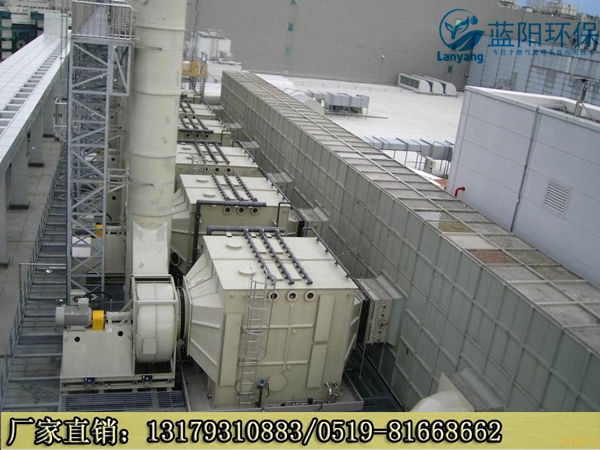

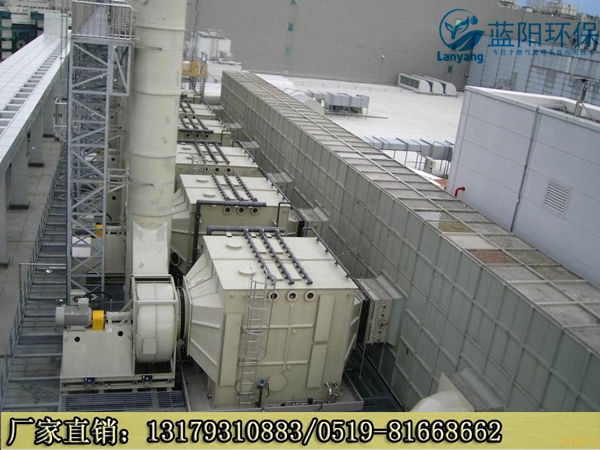

活性炭废气吸附塔

一、活性炭吸附塔概述

活性炭吸附塔又可称为活性炭吸附箱吸附器,活性炭吸附过滤器,活性炭吸附箱。HT系列|活性炭吸附过滤器(塔、箱)是我公司研制生产的一种废气过滤吸附异味的环保设备产品,活性炭吸附塔塔体可用不锈钢、碳钢、PP板等材质制作。活性炭吸附塔具有吸附效率高、适用面广、维护方便、能同时处理多种混合废气等优点,活性炭具有去除甲醛、苯、TVOC等有害气体和消毒除臭等作用,活性炭吸附塔现广泛用于 电子原件生产、电池(电瓶)生产、酸洗作业、实验室排风、冶金、化工、医药、涂装、食品、酿造等有机废气处理,其中喷漆废气处理的净化应用最为广泛。

活性炭废气吸附塔

一、活性炭吸附塔概述

活性炭吸附塔又可称为活性炭吸附箱吸附器,活性炭吸附过滤器,活性炭吸附箱。HT系列|活性炭吸附过滤器(塔、箱)是我公司研制生产的一种废气过滤吸附异味的环保设备产品,活性炭吸附塔塔体可用不锈钢、碳钢、PP板等材质制作。活性炭吸附塔具有吸附效率高、适用面广、维护方便、能同时处理多种混合废气等优点,活性炭具有去除甲醛、苯、TVOC等有害气体和消毒除臭等作用,活性炭吸附塔现广泛用于 电子原件生产、电池(电瓶)生产、酸洗作业、实验室排风、冶金、化工、医药、涂装、食品、酿造等有机废气处理,其中喷漆废气处理的净化应用最为广泛。

FRP glass steel tower mist purification tower \ \ \ FRP FRP exhaust tower packed tower, glass steel waste gas absorption tower, Lan Yang environmental protection hotline: 0519-8166866213179310883, welcome to contact us! ~

Technical execution standard:

(1) environmental protection law of the People's Republic of China;

(2) the comprehensive emission standard of air pollutants (GB16297-1996);

(3) emission standards for odor pollutants (GB14554-1993);

(4) ambient air quality standard (GB3095-1996);

(5) the noise standards and measurement methods of the factory plant boundary (GB12348 ~ 12349-90);

(6) occupational exposure limits for hazardous factors in Workplace (GBZ 2-2002);

(7) hygienic standard for design of industrial enterprises (GBZ 1-2002);

(8) Regulations on environmental protection of construction projects, order of the State Council of the People's Republic of China No. 253rd, No. 1998;

(9) no pungent odor emission;

Equipment composition and working principle

1, constitute

The acid mist absorber in acid system, water system, absorption system, discharge system of four parts. It is connected with the on-site storage tank to form a closed loop FOG absorption system.

2, working principle

Corrosion resistant pipe connected into a closed system with exhaust mist absorber mist inlet and the acid storage tank mouth, adding water from the water inlet and water spray system by adding water, sprayed down, released through absorption system makes fully absorbed by the water mist, and water solution through the water outlet, go to the pool.

Installation conditions

(1) the interior should have the power source, the diameter of pipe DN is larger than 20mm, the conventional power pressure should be 0.2 ~ 0.4Mpa;

(2) the equipment shall be provided with acid resistant ceramic tile on the floor of the working room, and the flushing water and drainage ditch shall be provided;

(3) acid storage tank owned customers should have a certain protective measures, such as fences, walls, and anti leakage device etc..

YL type mist purification tower also known as the acid mist absorber, gas is mainly used in various fields of various chemical, electronics, metallurgy, industrial production and purification. This type of equipment is mainly used to spray packing and tray gas-liquid exchange purification process of harmful gases, the harmful gases including hydrochloric acid fog, fog, mist, chromium sulfate, phosphate, nitrate fog fog hydrofluoric acid fog, hydrogen chloride, hydrogen sulfide, hydrogen cyanide, etc..

Working principle

This equipment uses sodium hydroxide solution as absorption and neutralizer to purify waste gas. The process is the use of harmful gas power of the centrifugal fan is pressed or suction inlet section, and then to flow to the first layer and the first filler spray absorption liquid contact reaction, by the exhaust gas to the primary absorption and with second spray absorption liquid again neutralization reaction. According to the specific data can be provided with a third filler gas spray to meet the purification requirement.

Structure and characteristics

The purification tower according to the user environment to provide round tower of glass steel integral winding or PP plastic welding of two materials, equipment segment connecting flange can effectively reduce the equipment leakage rate and bolt decay rate. The utility model is composed of a liquid storage tank, an air inlet section, a packing layer, a spray section, a dewatering and defoaming device and an exhaust port.

Its characteristics are: production of advanced technology, beautiful appearance, convenient installation and maintenance and the body of high strength, small occupied area, long service life (three years), the design and manufacture of flexible (can be determined according to the number of spray packing waste gas data users).

Activated carbon waste gas adsorption tower

An overview of activated carbon adsorption tower

Activated carbon adsorption tower also known as activated carbon adsorption tank adsorber, activated carbon filter, activated carbon adsorption tank. HT series | activated carbon filter (tower, box) is a waste gas filtering adsorption odor and I developed the production of environmental protection equipment, activated carbon adsorption tower is available, PP stainless steel and carbon steel plate and other materials. Adsorption of activated carbon adsorption tower with high efficiency, wide application, convenient maintenance, can also handle a variety of mixed gases etc., formaldehyde, benzene, TVOC and other harmful gases and disinfection deodorizing effects with the removal of activated carbon, activated carbon adsorption tower is now widely used in electronic components (battery) battery production, production, processing and pickling laboratory ventilation, metallurgy, chemical, pharmaceutical, food, brewing, coating and other organic waste, including lacquering treatment purification is the most widely used.

Activated carbon waste gas adsorption tower

An overview of activated carbon adsorption tower

Activated carbon adsorption tower also known as activated carbon adsorption tank adsorber, activated carbon filter, activated carbon adsorption tank. HT series | activated carbon filter (tower, box) is a waste gas filtering adsorption odor and I developed the production of environmental protection equipment, activated carbon adsorption tower is available, PP stainless steel and carbon steel plate and other materials. Adsorption of activated carbon adsorption tower with high efficiency, wide application, convenient maintenance, can also handle a variety of mixed gases etc., formaldehyde, benzene, TVOC and other harmful gases and disinfection deodorizing effects with the removal of activated carbon, activated carbon adsorption tower is now widely used in electronic components (battery) battery production, production, processing and pickling laboratory ventilation, metallurgy, chemical, pharmaceutical, food, brewing, coating and other organic waste, including lacquering treatment purification is the most widely used.

技术执行标准:

(1)《中华人民共和国环境保护法》;

(2)《大气污染物综合排放标准》(GB16297-1996);

(3)《恶臭污染物排放标准》(GB14554-1993);

(4)《环境空气质量标准》(GB3095-1996);

(5)《工厂企业厂界噪声标准及其测量方法》(GB12348~12349-90);

(6)《工作场所有害因素职业接触限值》(GBZ 2-2002);

(7)《工业企业设计卫生标准》(GBZ 1-2002);

(8)《建设项目环境保护条例》中华人民共和国国务院令第253号 1998;

(9) 无刺激性异味排放;

设备构成及工作原理

1、构 成

酸雾吸收器由酸雾进酸系统、加水系统、吸收系统、排放系统四大部分组成。它与现场储酸槽连接组成一个闭环酸雾吸收系统。

2、工作原理

酸雾吸收器的酸雾进口与储酸槽的排气口用耐腐蚀管道连接成密闭系统,从加水口加入水并通过加水系统进行水喷淋,均匀喷洒下来,经过吸收系统让酸雾充分被水吸收后释放,然后水溶液通过排水口排出,去到中和池。

安装条件

(1) 室内应具备动力水源,水管管径DN≥20mm,常规动力水压应为0.2~0.4Mpa;

(2) 设备工作间地面应铺设耐酸瓷砖,并设有冲洗用水源和排水沟;

(3) 客户自备的储酸槽应具备一定的防护措施,如护栏、护墙、以及防泄露等装置。

YL型酸雾净化塔又可称为酸雾吸收塔,主要应用于各种化工、电工电子、冶金、工业生产等多种领域的气体净化。本型号设备主要是采用喷淋填料及气液交换塔盘净化工艺处理有害气体、处理的有害气体包括盐酸雾、硫酸雾、铬酸雾、硝酸雾、磷酸雾、氢氟酸雾、氯化氢、硫化氢、氰化氢等。

工作原理

本设备采用氢氧化钠溶液为吸收中和剂来净化废气。其工作流程是有害气体利用离心风机的动力被压入或吸入进风段,再向上流动至第一填料层与第一级喷嘴喷出的中和吸收液接触反应、被初级吸收后的废气继续向上与第二级喷嘴喷出的中和吸收液再次发生中和反应,根据具体废气数据可以加装第三极填料喷淋段以满足净化要求。

结构及特点

本净化塔可根据用户使用环境提供玻璃钢整体缠绕或PP塑料焊接两种材质的圆形塔体,设备无分段连接法兰有效的降低了设备漏风率及连接螺栓的腐坏率。具体结构有储液箱、进风段、填料层、喷淋段、脱水除沫装置、排气口组成。

其特点是:制作工艺先进、外形美观、安装检修方便且主体强度高、占地面积小、使用寿命长(三年以上)、设计制造灵活(可根据用户的废气数据确定喷淋填料层数)。

活性炭废气吸附塔

一、活性炭吸附塔概述

活性炭吸附塔又可称为活性炭吸附箱吸附器,活性炭吸附过滤器,活性炭吸附箱。HT系列|活性炭吸附过滤器(塔、箱)是我公司研制生产的一种废气过滤吸附异味的环保设备产品,活性炭吸附塔塔体可用不锈钢、碳钢、PP板等材质制作。活性炭吸附塔具有吸附效率高、适用面广、维护方便、能同时处理多种混合废气等优点,活性炭具有去除甲醛、苯、TVOC等有害气体和消毒除臭等作用,活性炭吸附塔现广泛用于 电子原件生产、电池(电瓶)生产、酸洗作业、实验室排风、冶金、化工、医药、涂装、食品、酿造等有机废气处理,其中喷漆废气处理的净化应用最为广泛。

活性炭废气吸附塔

一、活性炭吸附塔概述

活性炭吸附塔又可称为活性炭吸附箱吸附器,活性炭吸附过滤器,活性炭吸附箱。HT系列|活性炭吸附过滤器(塔、箱)是我公司研制生产的一种废气过滤吸附异味的环保设备产品,活性炭吸附塔塔体可用不锈钢、碳钢、PP板等材质制作。活性炭吸附塔具有吸附效率高、适用面广、维护方便、能同时处理多种混合废气等优点,活性炭具有去除甲醛、苯、TVOC等有害气体和消毒除臭等作用,活性炭吸附塔现广泛用于 电子原件生产、电池(电瓶)生产、酸洗作业、实验室排风、冶金、化工、医药、涂装、食品、酿造等有机废气处理,其中喷漆废气处理的净化应用最为广泛。

FRP glass steel tower mist purification tower \ \ \ FRP FRP exhaust tower packed tower, glass steel waste gas absorption tower, Lan Yang environmental protection hotline: 0519-8166866213179310883, welcome to contact us! ~

Technical execution standard:

(1) environmental protection law of the People's Republic of China;

(2) the comprehensive emission standard of air pollutants (GB16297-1996);

(3) emission standards for odor pollutants (GB14554-1993);

(4) ambient air quality standard (GB3095-1996);

(5) the noise standards and measurement methods of the factory plant boundary (GB12348 ~ 12349-90);

(6) occupational exposure limits for hazardous factors in Workplace (GBZ 2-2002);

(7) hygienic standard for design of industrial enterprises (GBZ 1-2002);

(8) Regulations on environmental protection of construction projects, order of the State Council of the People's Republic of China No. 253rd, No. 1998;

(9) no pungent odor emission;

Equipment composition and working principle

1, constitute

The acid mist absorber in acid system, water system, absorption system, discharge system of four parts. It is connected with the on-site storage tank to form a closed loop FOG absorption system.

2, working principle

Corrosion resistant pipe connected into a closed system with exhaust mist absorber mist inlet and the acid storage tank mouth, adding water from the water inlet and water spray system by adding water, sprayed down, released through absorption system makes fully absorbed by the water mist, and water solution through the water outlet, go to the pool.

Installation conditions

(1) the interior should have the power source, the diameter of pipe DN is larger than 20mm, the conventional power pressure should be 0.2 ~ 0.4Mpa;

(2) the equipment shall be provided with acid resistant ceramic tile on the floor of the working room, and the flushing water and drainage ditch shall be provided;

(3) acid storage tank owned customers should have a certain protective measures, such as fences, walls, and anti leakage device etc..

YL type mist purification tower also known as the acid mist absorber, gas is mainly used in various fields of various chemical, electronics, metallurgy, industrial production and purification. This type of equipment is mainly used to spray packing and tray gas-liquid exchange purification process of harmful gases, the harmful gases including hydrochloric acid fog, fog, mist, chromium sulfate, phosphate, nitrate fog fog hydrofluoric acid fog, hydrogen chloride, hydrogen sulfide, hydrogen cyanide, etc..

Working principle

This equipment uses sodium hydroxide solution as absorption and neutralizer to purify waste gas. The process is the use of harmful gas power of the centrifugal fan is pressed or suction inlet section, and then to flow to the first layer and the first filler spray absorption liquid contact reaction, by the exhaust gas to the primary absorption and with second spray absorption liquid again neutralization reaction. According to the specific data can be provided with a third filler gas spray to meet the purification requirement.

Structure and characteristics

The purification tower according to the user environment to provide round tower of glass steel integral winding or PP plastic welding of two materials, equipment segment connecting flange can effectively reduce the equipment leakage rate and bolt decay rate. The utility model is composed of a liquid storage tank, an air inlet section, a packing layer, a spray section, a dewatering and defoaming device and an exhaust port.

Its characteristics are: production of advanced technology, beautiful appearance, convenient installation and maintenance and the body of high strength, small occupied area, long service life (three years), the design and manufacture of flexible (can be determined according to the number of spray packing waste gas data users).

Activated carbon waste gas adsorption tower

An overview of activated carbon adsorption tower

Activated carbon adsorption tower also known as activated carbon adsorption tank adsorber, activated carbon filter, activated carbon adsorption tank. HT series | activated carbon filter (tower, box) is a waste gas filtering adsorption odor and I developed the production of environmental protection equipment, activated carbon adsorption tower is available, PP stainless steel and carbon steel plate and other materials. Adsorption of activated carbon adsorption tower with high efficiency, wide application, convenient maintenance, can also handle a variety of mixed gases etc., formaldehyde, benzene, TVOC and other harmful gases and disinfection deodorizing effects with the removal of activated carbon, activated carbon adsorption tower is now widely used in electronic components (battery) battery production, production, processing and pickling laboratory ventilation, metallurgy, chemical, pharmaceutical, food, brewing, coating and other organic waste, including lacquering treatment purification is the most widely used.

Activated carbon waste gas adsorption tower

An overview of activated carbon adsorption tower

Activated carbon adsorption tower also known as activated carbon adsorption tank adsorber, activated carbon filter, activated carbon adsorption tank. HT series | activated carbon filter (tower, box) is a waste gas filtering adsorption odor and I developed the production of environmental protection equipment, activated carbon adsorption tower is available, PP stainless steel and carbon steel plate and other materials. Adsorption of activated carbon adsorption tower with high efficiency, wide application, convenient maintenance, can also handle a variety of mixed gases etc., formaldehyde, benzene, TVOC and other harmful gases and disinfection deodorizing effects with the removal of activated carbon, activated carbon adsorption tower is now widely used in electronic components (battery) battery production, production, processing and pickling laboratory ventilation, metallurgy, chemical, pharmaceutical, food, brewing, coating and other organic waste, including lacquering treatment purification is the most widely used.

相关产品推荐

-

湖州废气处理_湖州工业废气处理_湖州活性炭吸附塔 厂家定制

湖州废气处理_湖州工业废气处理_湖州活性炭吸附塔 厂家定制

-

南京废气处理,徐州废气处理,苏州废气处理 加工定制

南京废气处理,徐州废气处理,苏州废气处理 加工定制

-

印刷厂废气处理-制药厂废气处理-喷涂厂废气处理-化工厂废气处理-喷漆厂废气处理

印刷厂废气处理-制药厂废气处理-喷涂厂废气处理-化工厂废气处理-喷漆厂废气处理

-

UV光解氧化设备/UV光解废气处理/uv光解除臭设备/uv光催化氧化设备 供应厂家

UV光解氧化设备/UV光解废气处理/uv光解除臭设备/uv光催化氧化设备 供应厂家

-

有机废气净化、废气净化设备、废气净化工程、废气净化装置 环保达标

有机废气净化、废气净化设备、废气净化工程、废气净化装置 环保达标

-

电子厂废气处理-鱼粉厂废气处理-电镀厂废气处理-皮革厂废气处理 厂家生产

电子厂废气处理-鱼粉厂废气处理-电镀厂废气处理-皮革厂废气处理 厂家生产

-

农药厂废气处理\橡胶厂废气处理\家具厂废气处理\污水厂废气处理\冶炼厂废气处理

农药厂废气处理\橡胶厂废气处理\家具厂废气处理\污水厂废气处理\冶炼厂废气处理

-

活性炭吸附装置-活性炭吸附设备-填料塔-玻璃钢废气处理塔-专业厂家

活性炭吸附装置-活性炭吸附设备-填料塔-玻璃钢废气处理塔-专业厂家

-

有机废气净化塔,有机废气处理塔,喷漆废气净化塔,盐酸废气净化塔 加工定制

有机废气净化塔,有机废气处理塔,喷漆废气净化塔,盐酸废气净化塔 加工定制

-

专注于聚丙烯废气吸收塔-吸附塔-不锈钢废气塔-不锈钢废气处理塔

专注于聚丙烯废气吸收塔-吸附塔-不锈钢废气塔-不锈钢废气处理塔