厂商 :北京华湄世贸技术发展有限公司总部

北京市 北京市- 主营产品:

- 木工字梁模板体系

- 清水混凝土模板

- 单侧支模

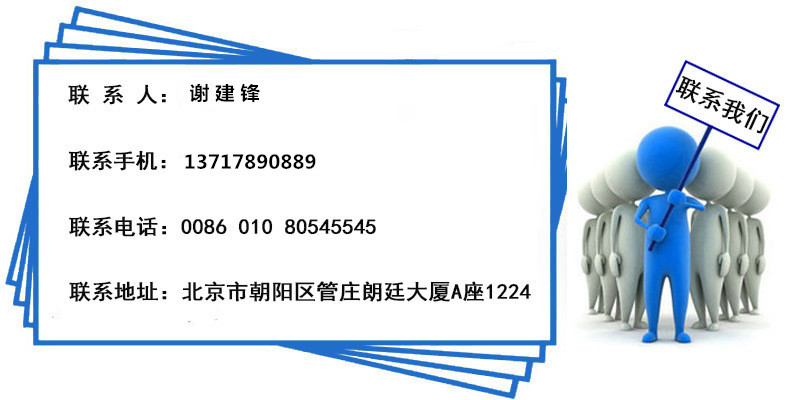

联系电话 :13717890889

商品详细描述

混凝土建筑模板哪家好 混凝土建筑模板厂家直销

相关产品推荐

-

钢模板单边支模 华湄支模架H=3600 超高墙体单面支模 地铁车站地下室车库超高单面墙 钢模板单边支模

钢模板单边支模 华湄支模架H=3600 超高墙体单面支模 地铁车站地下室车库超高单面墙 钢模板单边支模

-

地铁施工用单侧墙模板@厂家租赁单侧模板 华湄模板厂家全国租赁地铁施工用三角背撑三角支架加固体系 单侧支架H=3600

地铁施工用单侧墙模板@厂家租赁单侧模板 华湄模板厂家全国租赁地铁施工用三角背撑三角支架加固体系 单侧支架H=3600

-

北京地铁施工用单侧模板@单面模板厂家 租赁单侧墙模板三角架,单边模三角架 京津冀单侧墙模板三角架,单边模三角架

北京地铁施工用单侧模板@单面模板厂家 租赁单侧墙模板三角架,单边模三角架 京津冀单侧墙模板三角架,单边模三角架

-

租赁地铁地下室施工用单侧支模体系单侧三角架

租赁地铁地下室施工用单侧支模体系单侧三角架

-

租赁地铁车辆段施工用单侧支模体系

租赁地铁车辆段施工用单侧支模体系

-

全国租赁单侧支模体系单边模加固

全国租赁单侧支模体系单边模加固

-

单边墙模板系统在地铁车站、地下室外墙结构上的应用

单边墙模板系统在地铁车站、地下室外墙结构上的应用

-

厂家提供租赁地铁单侧单面模板 租赁地铁单侧支模单面模

厂家提供租赁地铁单侧单面模板 租赁地铁单侧支模单面模

-

单侧支模三角架厂家提供租赁单侧模 厂家提供租赁单侧模板三角架

单侧支模三角架厂家提供租赁单侧模 厂家提供租赁单侧模板三角架

-

单侧支模哪家好 供应地铁地下室施工用单侧支模体系

单侧支模哪家好 供应地铁地下室施工用单侧支模体系