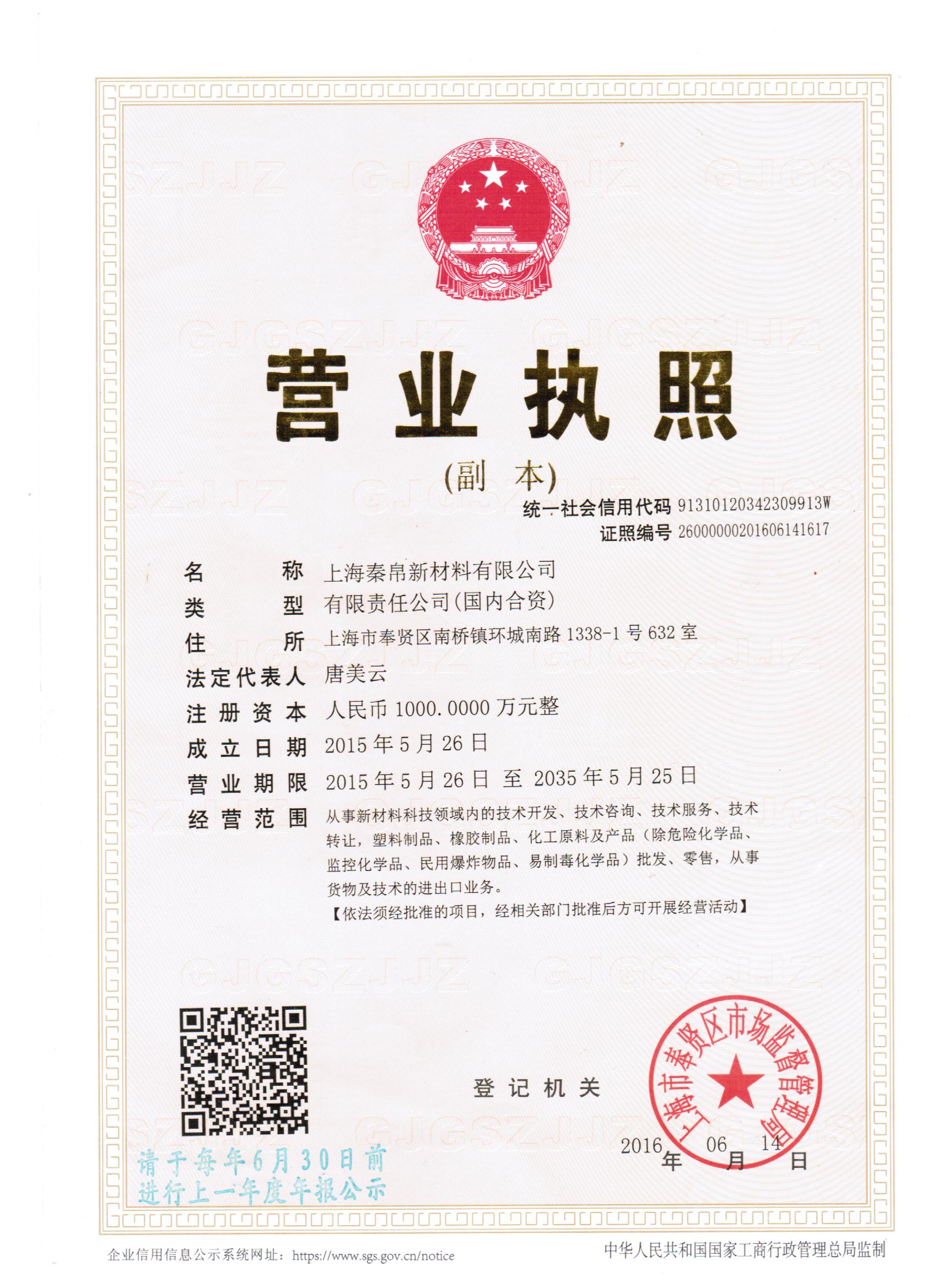

厂商 :上海秦帛新材料有限公司

上海市 上海市- 主营产品:

- PP

- POM

- PA66

Physical Properties物理性质 Metric公制数据 English英制数据 Comments测试方法 Density密度 1.20 g/cc 0.0434 lb/in? ISO 1183 Moisture Absorption at Equilibrium吸湿平衡 0.10 % 0.10 % 23°C / 50% RH; ISO 62 Water Absorption at Saturation饱和水吸收率 0.20 % @Temperature 23.0 °C 0.20 % @Temperature 73.4 °F ISO 62 Linear Mold Shrinkage, Flow线性收缩率/流动 0.0040 - 0.0060 cm/cm @Thickness 3.20 mm 0.0040 - 0.0060 in/in @Thickness 0.126 in SABIC Method Melt Flow熔体流动速率 15 g/10 min @Load 2.16 kg, Temperature 260 °C 15 g/10 min @Load 4.76 lb, Temperature 500 °F [cm^3/10 min] Melt Volume Rate; ISO 1133 18 g/10 min @Load 2.16 kg, Temperature 260 °C 18 g/10 min @Load 4.76 lb, Temperature 500 °F ASTM D 1238 Mechanical Properties力学性能 Metric公制数据 English英制数据 Comments测试方法 Tensile Strength at Break断裂拉伸强度 50.0 MPa 7250 psi 50 mm/min; ISO 527 58.0 MPa 8410 psi Type I, 50 mm/min; ASTM D 638 Tensile Strength, Yield屈服拉伸强度 65.0 MPa 9430 psi Type I, 50 mm/min; ASTM D 638 65.0 MPa 9430 psi 50 mm/min; ISO 527 Elongation at Break断裂伸长率 90 % 90 % 50 mm/min; ISO 527 100 % 100 % Type I, 50 mm/min; ASTM D 638 Elongation at Yield屈服伸长率 4.0 % 4.0 % 50 mm/min; ISO 527 4.1 % 4.1 % Type I, 50 mm/min; ASTM D 638 Tensile Modulus拉伸模量 2.60 GPa 377 ksi 5 mm/min; ASTM D 638 2.60 GPa 377 ksi 1 mm/min; ISO 527 Flexural Yield Strength弯曲屈服强度 96.0 MPa 13900 psi 2 mm/min; ISO 178 104 MPa 15100 psi 1.3 mm/min, 50 mm span; ASTM D 790 Flexural Modulus弯曲弹性模量 2.50 GPa 363 ksi 1.3 mm/min, 50 mm span; ASTM D 790 2.50 GPa 363 ksi 2 mm/min; ISO 178 Izod Impact, Notched悬臂梁缺口冲击强度 1.75 J/cm @Temperature -30.0 °C 3.28 ft-lb/in @Temperature -22.0 °F ASTM D 256 7.00 J/cm @Temperature 23.0 °C 13.1 ft-lb/in @Temperature 73.4 °F ASTM D 256 Izod Impact, Notched悬臂梁缺口冲击强度 (ISO) 10.0 kJ/m? @Temperature -30.0 °C 4.76 ft-lb/in? @Temperature -22.0 °F 80*10*4; ISO 180/1A 10.0 kJ/m? @Temperature -30.0 °C 4.76 ft-lb/in? @Temperature -22.0 °F 80*10*3; ISO 180/1A 20.0 kJ/m? @Temperature 23.0 °C 9.52 ft-lb/in? @Temperature 73.4 °F 80*10*3; ISO 180/1A 25.0 kJ/m? @Temperature 23.0 °C 11.9 ft-lb/in? @Temperature 73.4 °F 80*10*4; ISO 180/1A Charpy ImPAct, Notched夏比缺口冲击 1.00 J/cm? @Temperature -30.0 °C 4.76 ft-lb/in? @Temperature -22.0 °F V-notch Edgew 80*10*3 sp=62mm; ISO 179/1eA 2.00 J/cm? @Temperature 23.0 °C 9.52 ft-lb/in? @Temperature 73.4 °F V-notch Edgew 80*10*3 sp=62mm; ISO 179/1eA 2.20 J/cm? @Temperature 23.0 °C 10.5 ft-lb/in? @Temperature 73.4 °F V-notch Edgew 80*10*4 sp=62mm; ISO 179/1eA Impact Test冲击试验数据 65.0 J @Temperature 23.0 °C 47.9 ft-lb @Temperature 73.4 °F Instrumented Impact Total Energy; ASTM D 3763 Electrical Properties电性能 Metric公制数据 English英制数据 Comments测试方法 Volume ResiSTivity体积电阻率 >= 1.00e+15 ohm-cm >= 1.00e+15 ohm-cm IEC 60093 Surface Resistance表面电阻 >= 1.00e+15 ohm >= 1.00e+15 ohm ROA; IEC 60093 Dielectric Strength介电强度 17.0 kV/mm @Thickness 3.20 mm 432 kV/in @Thickness 0.126 in in oil; IEC 60243-1 25.0 kV/mm @Thickness 1.60 mm 635 kV/in @Thickness 0.0630 in in oil; IEC 60243-1 35.0 kV/mm @Thickness 0.800 mm 889 kV/in @Thickness 0.0315 in in oil; IEC 60243-1 Comparative Tracking Index跟踪指数 175 - 250 V 175 - 250 V PLC code 3; UL 746A Hot Wire Ignition, HWI热线圈点燃测试 15 - 30 sec 15 - 30 sec PLC code 3; UL 746A High Amp Arc Ignition, HAI高电流电弧点燃测试 >= 120 arcs >= 120 arcs surface, PLC code 0; UL 746A Thermal Properties热性能 Metric公制数据 English英制数据 Comments测试方法 CTE, linear, Parallel to Flow线性热膨胀系数 75.0 ?m/m-°C @Temperature -40.0 - 40.0 °C 41.7 ?in/in-°F @Temperature -40.0 - 104 °F ASTM E 831 75.0 ?m/m-°C @Temperature -40.0 - 40.0 °C 41.7 ?in/in-°F @Temperature -40.0 - 104 °F ISO 11359-2 CTE, linear, Transverse to Flow线性热膨胀系数/横向 75.0 ?m/m-°C @Temperature -40.0 - 40.0 °C 41.7 ?in/in-°F @Temperature -40.0 - 104 °F ASTM E 831 75.0 ?m/m-°C @Temperature -40.0 - 40.0 °C 41.7 ?in/in-°F @Temperature -40.0 - 104 °F ISO 11359-2 Thermal Conductivity导热系数 0.200 W/m-K 1.39 BTU-in/hr-ft?-°F ISO 8302 Deflection Temperature at热变形温度 0.46 MPa (66 psi) 100 °C @Thickness 3.20 mm 212 °F @Thickness 0.126 in unannealed; ASTM D 648 Deflection Temperature at热变形温度 1.8 MPa (264 psi) 93.0 °C 199 °F Flatw 80*10*4 sp=64mm; ISO 75/Af 89.0 °C @Thickness 3.20 mm 192 °F @Thickness 0.126 in unannealed; ASTM D 648 99.0 °C @Thickness 6.40 mm 210 °F @Thickness 0.252 in unannealed; ASTM D 648 Vicat Softening Point维卡软化点 110 °C 230 °F Rate B/50; ASTM D 1525 110 °C 230 °F Rate B/50; ISO 306 113 °C 235 °F Rate B/120; ISO 306 UL RTI, Electrical相对温度指数 90.0 °C 194 °F UL 746B UL RTI, Mechanical with Impact机械冲击热指数 90.0 °C 194 °F UL 746B UL RTI, Mechanical without Impact无机械冲击热指数 90.0 °C 194 °F UL 746B Flammability, UL94阻燃等级 V-0 @Thickness 0.600 mm V-0 @Thickness 0.0236 in UL 94 V-0 @Thickness 0.750 mm V-0 @Thickness 0.0295 in UL 94 5VA @Thickness 1.50 mm 5VA @Thickness 0.0591 in UL 94 5VA @Thickness 3.00 mm 5VA @Thickness 0.118 in UL 94 Oxygen Index氧指数 34 % 34 % LOI; ISO 4589 Glow Wire Test灼热丝试验 775 °C @Thickness 3.00 mm 1430 °F @Thickness 0.118 in Glow Wire Ignitability Temperature; IEC 60695-2-13 775 °C @Thickness 0.750 mm 1430 °F @Thickness 0.0295 in Glow Wire Ignitability Temperature; IEC 60695-2-13 775 °C @Thickness 1.50 mm 1430 °F @Thickness 0.0591 in Glow Wire Ignitability Temperature; IEC 60695-2-13 800 °C @Thickness 3.00 mm 1470 °F @Thickness 0.118 in Glow Wire Ignitability Temperature; IEC 60695-2-13 825 °C @Thickness 1.00 mm 1520 °F @Thickness 0.0394 in Glow Wire Ignitability Temperature; IEC 60695-2-13 960 °C @Thickness 0.750 mm 1760 °F @Thickness 0.0295 in Glow Wire Flammability Index; IEC 60695-2-12 960 °C @Thickness 0.750 mm 1760 °F @Thickness 0.0295 in Glow Wire Flammability Index 960°C, passes at, by VDE; IEC 60695-2-12 SABIC CYCOLOY CX7240 PC/ABS生物相容的HC生物相容树脂组合是一个无定形的PC/ABS树脂,是很好的候选人为医疗市场。核心产品:聚碳酸酯/烯腈烯烯树脂提供了两个世界上最的性能平衡,对模具和oem都有吸引力。尺寸稳定性高模数树脂的组合是一个非晶的,填充的,PC/ABS共混物,在FR和非FR产品中提供了出色的尺寸稳定性。阻燃性树脂系列产品是一种适用于注塑成型、挤出成型和热压成型的非晶型PC/ABS复合材料。改善韧性基于标准的巨大力量聚碳酸酯?树脂、高影响树脂的这个家庭有更大的影响性能和低温韧性。 特的视觉效果组合是一系列的树脂,可以通过使用先进的颜料和聚合物技术在美学和功能上增强你的产品。如流线还原、陶瓷、光蔽和激光焊接等,可提供当今高技术部件所需的美学和功能分化。

PP POM PA66 PC PBT PMMA ABS TPU

公司简介

公司简介

上海秦帛新材料有限公司

上海秦帛新材料有限公司