厂商 :东莞市千色变新材料有限公司

广东 东莞市- 主营产品:

- 温变粉,光变粉,荧光

- 温变油墨,光变油墨

- 紫外荧光防伪油墨,遇

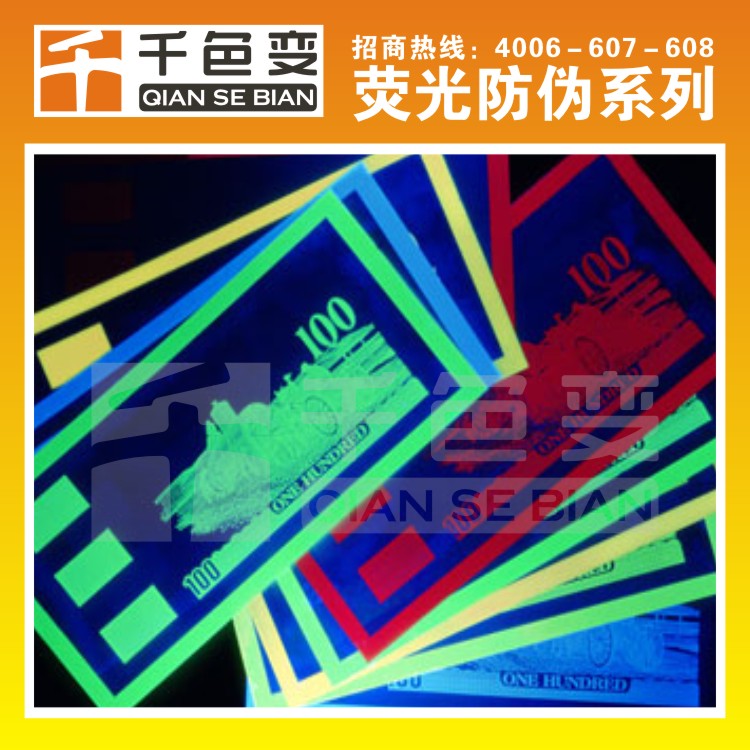

紫外荧光油墨Fluorescent uv ink

荧光油墨是印刷中应用比较多的油墨之一,其主要成分是荧光颜料。荧光颜料属功能性发光颜料,与一般颜料的区别在于当外来光(含紫外光)照射时,能吸收一定形态的能,而激发光子,以低可见光形式将吸收的能量释放出来,从而产生不同色相的荧光现象。不同色光结合形成异常鲜艳的色彩,而当光停止照射后,发光现象即消失,因此称为荧光颜料。荧光颜料与高分子树脂连接料、溶剂和助剂配比,经研磨可制得荧光油墨。

紫外荧光油墨,又称无色荧光油墨和隐形油墨,是在油墨中加入荧光颜料而制成的。应用紫外光(200—400nm)照射激发而发出可见光(400—800nm)的特种油墨,称为紫外荧光油墨。根据激发波长不同分为短波和长波。激发波长为254nm的称为短波紫外荧油墨,激发波长为365nm的称为长波紫外荧光油墨,可显示红、黄、绿、蓝 等颜色。

紫外荧光油墨适用印刷方式:丝印、胶印、转印、移印

紫外荧光油墨适用底材为:纸张 布料 金属 陶瓷 塑料等

紫外荧光油墨应用范围:证、标签、包装等。

紫外荧光无色丝印油墨外观是半透明液体状,无色胶印类为乳黄色糊状。

荧光油墨丝印用250-300目,可用783溶剂稀释,稀释比例为3%-5%

紫外荧光油墨的干燥当时是自干或UV烤干,丝印是自干,胶印是UV烤干

Fluorescent uv ink for printing: screen printing, offset printing, transfer printing, pad printing

Fluorescent uv ink applicable substrate for: paper metal ceramic plastic cloth, etc

Fluorescent uv ink application range: paper, certificate, labels, packing and so on.

Ultraviolet fluorescence colorless, screen printing ink appearance is translucent liquid, colorless offset printing for the part that paste.

Fluorescent screen printing ink with a 250-300 mesh, 783 available solvent dilution, dilution ratio of 3% to 3%

Fluorescent UV ink drying was from dry or UV dry, screen printing is the dry, offset printing is the UV to dry

防伪特征及分类Security features and classification

荧光油墨分为紫外荧光油墨无色荧光油墨Fluorescent ink is divided into fluorescent uv ink colorless fluorescent ink

1、隐形UV紫外荧光油墨防伪:

所用材料为隐形荧光油墨,印刷工艺简单。该油墨印刷出隐形图案或文字,在紫外光照射厂。呈现出清晰光亮的荧光图案。色彩鲜艳。该防伪检测方便,只要有一紫外光源或验钞机即可。由于隐形荧光油墨是隐形即无色,在印刷时肉眼看不见也即无任何机器识别的跟踪标记。所以套印起来难度较大,但该种防伪隐蔽性较好,防伪力度更强, 日前国内大多数包装都采用该种隐形荧光油墨。

Invisible UV fluorescent UV ink anti-counterfeiting:

Materials used for invisible fluorescent ink, printing process simple. The ink printed stealth design or text, ultraviolet light in the factory. Present a clear pattern of fluorescent light. Bright colors. The security detection is convenient, as long as there is a uv light source or counterfeit detector. Due to the invisible fluorescent ink is invisible or colorless, invisible to the naked eye when printed is no machine identification tracking tags. So set up is difficult, but this kind of anti-counterfeiting concealment is better, stronger anti-counterfeiting efforts, most recently domestic pharmaceutical packaging USES this kind of invisible fluorescent ink.

2、有形UV紫外荧光油墨防伪:所用材料为有形荧光油墨,印刷工艺简单,印刷效果同普通油墨印刷效果一样,但在紫外光照射下,印刷品呈现出异常的亮光, 此时可区别于普通油墨。

Visible UV fluorescent UV ink anti-counterfeiting: materials for the visible fluorescent inks, printing process simple, overprint accurate, the printing effect, like normal ink printing effect, but under UV irradiation, print appear abnormal light, can be different from the ordinary ink at this time.

适用范围和注意事项Scope of application and matters needing attention

荧光油墨适于纸张、薄膜等的印刷。由于无机荧光物是由晶体发光的,若压力过大可使晶体破裂,从而使发光亮度降低,所以一般不采用凸版印刷,很适用于网版印刷以及凹印等。大多数荧光油墨的流变特性呈仿塑性流动,黏度小,这项特性决定了其印刷工艺与普通油墨的印刷工艺有很大区别。而在进行凹印和网印时,除注意其黏性、连接料、干燥性等特性外,还要注意其印刷压力的调节,不能使印刷压力过大而影响印刷效果。 在进行网印时,要注意以下几点:

(1)荧光油墨适合于200目以下的丝网;

(2)印刷品的着墨量在50~60g/㎡时,其发色和耐光性比较理想;

(3)在承印物是透明物体时,应先印一次白色油墨,这样可提高荧光效果。

Fluorescent ink is suitable for printing paper and vinyl film, etc. Due to inorganic fluorescent material is made of crystal shine, if stress can make crystal break, so that the luminous intensity is reduced, so you don't normally use letterpress, very suitable for screen printing and gravure. Most of the rheological properties of fluorescent ink in plastic flow, viscosity is small, this feature determines its printing with ordinary ink printing process is very different. In gravure and screen printing, in addition to pay attention to the character of viscosity, connection material, dry, also note the printing pressure adjustment, does not affect the printing effect to make the printing pressure is too large. In the screen printing, attention should be paid to the following:

(1) the fluorescent ink suitable for below 200 mesh screen;

(2) the amount of inking print in 50 ~ 60 g / ㎡, the hair color and light fastness is ideal;

(3) in the substrates are transparent objects, you should print a white ink, which can improve the effect of fluorescence.