厂商 :浙江温州欧创机械有限公司

浙江 温州- 主营产品:

- 气柱袋设备

- 气柱袋生产设备

- 气柱袋生产线

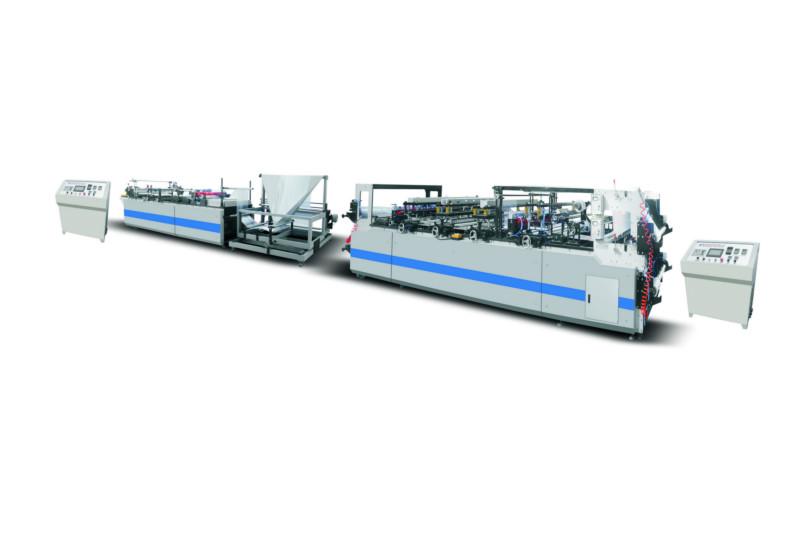

OC1200-B型机械式缓冲气柱袋生产流水线

(双模具)

Mechanical Cushion Airbag Production Line—FABS46 DM

(Dual Mould)

简介:

机械式缓冲气柱袋生产流水线(双模具)是我公司根据市场需要而研制的,在原来设计结构上增加了一副模具在设备上面,使客户省去换模具带来的不必要的浪费。适用于PE共挤膜等卷材生产各种缓冲气柱袋、缓冲气垫、填充气袋。生产出来的产品有低成本、省空间、可回收、缩减包装流程,节省人力、无污染性、同时还能提供长时间储运不漏气的抗震保护等特点。广泛应用于各个包装领域,如电子产品、陶瓷、精密仪器、家具、照明产品、汽配、硒鼓、红酒、奶粉、快递物流等各种行业。

Introduction

FABS46 is a mechanical designed production line (with Dual Mould) according to customer and market demand, with additional mould which can make different products without changing mould, suitable for all kinds of airbag, cushion bag, filling bag by PE Co-extruded film. The products are having the advantages of low cost, saving space, re-cycling, easy packing, manpower saving, no pollution and long time airtight for stock and transportation. Widely used in all kinds of packing industries, such like electronic, ceramic, furniture, lights, toner, wine, milk powder etc fragile, precision and luxurious products; also widely used in express and logistics industries.

特点:

1、 主控电路采用进口PLC与变频器联合控制,良好的人机界面,操作集中直观、方便;

2、 任意定长即设即用、方便简单、光电自动跟踪,准确平稳;

3、 整机采用变频器控制,变频范围宽,速度调节范围大,实现无级变速。即调即用,匹配完美。

4、 双纠偏装置分上膜纠偏,下膜纠偏两套机构,其作用在于通过光电检测自动跟踪纠正调整薄膜跑偏

5、 双模具设计可以在不更换模具的情况下生产另外一种产品,从而提高生产效率和产品一致性,同时可以减少时间和材料的浪费

Features

1. Automatic Machine controlled by PLC and Inverter. Easy operation control panel.

2. Parameter setting effect immediately, tracked by electronic eyes, smooth and accurate.

3. Widely frequency range of inverters are controlling the whole production line, stepless speed changing, individual release and pick up motors make production more smooth and effective.

4. Release and pick up roll holders are using air expansion shaft, easy load and unload.

5. Dual mould can make two kinds of products without changing mould, so that production efficiency and consistency will be increased, and time and material will be saved.

主要技术参数

|

标准机规格性能及技术参数 |

规格类型 |

OC1200-B(双模具) |

|

A机压柱速度 (米/分) |

8-12(速度可调) |

|

|

B机制袋速度 (个/分) |

小于等于50 |

|

|

最大膜宽度(毫米) |

1200 |

|

|

最大上卷直径(毫米) |

¢500(约1600米) |

|

|

收放卷气胀轴直径(毫米) |

¢74mm |

|

|

总功率(千瓦) |

14.5+3.2(A机+B机) |

|

|

机器净重(千克) |

2150+1200+700(A机+B机+三角机) |

|

|

机器外形尺寸(长×宽×高)(毫米) |

A机:6100×1585×1470 |

|

|

B机:3185×1295×1380 |

||

|

三角机:1900×1600×1600 |

||

|

机器噪声(分贝) |

≤55分贝 |

|

|

成袋合格率(百分比) |

≥97% |

|

|

封口压力(牛顿/毫米2) |

15 |

|

|

电源类型 |

380V 50Hz |

|

|

包装膜材料 |

PE共挤膜等。 |

|

Specification for FABS46 DM

|

|

Model |

FBAS46 DM (oc1200-B) |

|

Part A air column making speed (meter/min) |

8-12 (Adjustable) |

|

|

Part B air bag making speed(pcs/min) |

≤50 |

|

|

Max loading width(mm) |

1200 |

|

|

Max loading Diameter(mm) |

¢500(=length 1600m) |

|

|

Roll holer Diameter(mm) |

¢74mm |

|

|

Total power(KW) |

14.5+3.2(Part A+Part B) |

|

|

Net weight(KG) |

2150+1200+700(Part A+PartB+Folder) |

|

|

Dimensions(Length×Width×Height)(mm) |

Part A:6100×1585×1470 |

|

|

Part B:3185×1295×1380 |

||

|

Folder:1900×1600×1600 |

||

|

Noise(DB) |

≤55DB |

|

|

Yield(%) |

≥97% |

|

|

Pressure(N/mm2) |

15 |

|

|

Power supply |

380V 50Hz |

|

|

Raw material |

PE co-extruded film, etc. |

|

产品实例