厂商 :深圳市红叶杰科技有限公司

广东省 深圳市- 主营产品:

- 硅胶

- 硅橡胶

- 液体硅胶

联系电话 :18938867511

商品详细描述

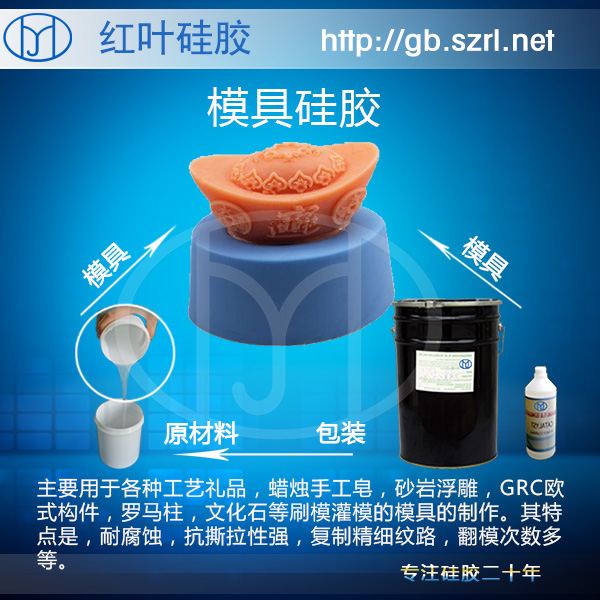

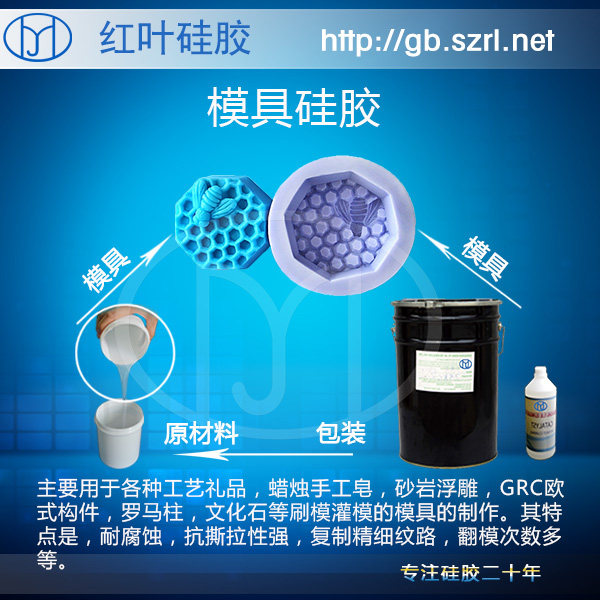

模具硅胶RTV-2 silicone rubber

模具硅胶的用途及应用领域

模具硅胶主要用于波丽树脂,环氧树指,石膏工艺品、肥皂,蜡烛灯饰,建筑装饰,浮雕家私,塑胶玩具工艺品,礼品文具,大型雕像,文物产品复制等产品的模具制作。

模具硅胶的特点

模具硅胶的特点是拉力好,撕裂强度好,耐高温,翻模次数多,可反复使用。

618#硬度较软适合于做小件的,产品图案精密细小或花纹复杂的并且很难脱模的小件复杂产品的模具制作。

725#硬度适中,它既可以用来做工艺品,也可用来做家私装修材料,既可以做大件产品也可以做小件产品。

728#硬度大,主要用于大件产品开分片模或片模,如大型的浮雕塑像,人物复制,家具家私,建筑装饰,大型水泥模具等制作。

模具硅胶产品用途 :

大件产品、开分片模、浮雕、佛像、工艺礼品制作模具 、 玻璃工艺、灯饰、蜡烛、人物复制制作模具之用途 、玩具、礼品、花纹精细的产品,用于包模、灌注模具产品

综合描述:

模具硅胶的优点是拉力好,撕裂强度好,耐高温,翻模次数多,可反复使用,适合小件产品,精密细小或花纹复杂的并且很难脱模的复杂产品的模具制作,并且收缩率可以达到千分之二。RTV-2、模具硅胶、矽胶,统称双组份室温硫化硅橡胶,它具有优异的流动性,良好的操作性,室温下加入固化剂2%—3%,30分钟还可操作,2—3小时后会生成,具有不变形、耐高温、耐酸碱,不膨胀的弹性硅胶模具,是POLI工艺品、树脂工艺品、灯饰、蜡烛等工艺品的复模及精密的模具制造。

本公司郑重承诺,凡购买红叶杰科技有限公司的产品,在三个月内,如有客户因质量问题,本公司负责包退、包换,并且服务跟踪到户,现场为客户做产品演示。免费为客户解决技术难题,免费提供开模技术,免费提供移印硅胶的使用技术及移印胶头制作技术。解决您的后顾之忧,让您的公司做出一流的产品是我们公司的追求。本公司欢迎新老客户及各地经销商前来洽谈业务,合作代理。让我们携手奋进,共创辉煌。

Molding silicone rubber

Usage:

For toy gifts and craftwork gift, products with complex fine details, and made in pouring way.

Description:

HY-638# silicon rubber is mainly used for toy gifts and craftwork gifts with the advantages of good tensile strength, high tear strength, high temperature resistance, high duplication times and repeated use, etc. It is suitable for small products or fine and precision products which is difficult to demould. This silicone rubber is one of the products with the highest use level in the production of craftwork gifts and the shrinkage is up to 2‰.

Silicon rubber for mold making applications:

Silicon rubber for molding making is primarily intended for poly resin crafts, PU crafts, PU resin crafts ,gypsum crafts ,unsaturated resin crafts, lighting and candles crafts ,plastic toy , stationery gifts crafts industry, a large statue Buddha, relievo furniture, furniture decorative materials, statues Buddha, artifacts copied, building decoration materials, large-scale cement mold, artificial fossils Factory, Europe component factory, simulation landscapes, animals and plants sculpture, sandstone crafts and so on.

Silicon rubber for mold making features description:

Silicon rubber for mold making is white or red flowing liquid with general hardness of 22-50A°after curing. Molding silicon rubber is a kind elastic silicon rubber mold which features with resistance to deformation, high-temperature, acid-alkali and expansion as well as high reproduction times, good tensile strength, tear strength and elongation.

Silicon rubber for mold making operations:

If the customer wants to make large products and large size molds, the mold should be made of silicon rubber with high hardness. On the contrary,if the mold with fine and precision patterns, it should be made of silicon with low hardness. The amount of the curing agent depends on the actual requirements of the customer. If molds requiring fast drying and demold, more curing agent is needed; contrarily,if molds requiring slower drying and demold, less curing agent is needed.

(Note: our company does not recommend you to add silicone oil. If a special soft silicon mold or fine detailed and complex patterns products are required, 5%-10% silicone oil can be added to soften the mold for easy demould.)

Frequently asked questions of molding silicone rubber

Why does the silicone rubber mold have few molding times?

模具硅胶的用途及应用领域

模具硅胶主要用于波丽树脂,环氧树指,石膏工艺品、肥皂,蜡烛灯饰,建筑装饰,浮雕家私,塑胶玩具工艺品,礼品文具,大型雕像,文物产品复制等产品的模具制作。

模具硅胶的特点

模具硅胶的特点是拉力好,撕裂强度好,耐高温,翻模次数多,可反复使用。

618#硬度较软适合于做小件的,产品图案精密细小或花纹复杂的并且很难脱模的小件复杂产品的模具制作。

725#硬度适中,它既可以用来做工艺品,也可用来做家私装修材料,既可以做大件产品也可以做小件产品。

728#硬度大,主要用于大件产品开分片模或片模,如大型的浮雕塑像,人物复制,家具家私,建筑装饰,大型水泥模具等制作。

模具硅胶产品用途 :

大件产品、开分片模、浮雕、佛像、工艺礼品制作模具 、 玻璃工艺、灯饰、蜡烛、人物复制制作模具之用途 、玩具、礼品、花纹精细的产品,用于包模、灌注模具产品

综合描述:

模具硅胶的优点是拉力好,撕裂强度好,耐高温,翻模次数多,可反复使用,适合小件产品,精密细小或花纹复杂的并且很难脱模的复杂产品的模具制作,并且收缩率可以达到千分之二。RTV-2、模具硅胶、矽胶,统称双组份室温硫化硅橡胶,它具有优异的流动性,良好的操作性,室温下加入固化剂2%—3%,30分钟还可操作,2—3小时后会生成,具有不变形、耐高温、耐酸碱,不膨胀的弹性硅胶模具,是POLI工艺品、树脂工艺品、灯饰、蜡烛等工艺品的复模及精密的模具制造。

本公司郑重承诺,凡购买红叶杰科技有限公司的产品,在三个月内,如有客户因质量问题,本公司负责包退、包换,并且服务跟踪到户,现场为客户做产品演示。免费为客户解决技术难题,免费提供开模技术,免费提供移印硅胶的使用技术及移印胶头制作技术。解决您的后顾之忧,让您的公司做出一流的产品是我们公司的追求。本公司欢迎新老客户及各地经销商前来洽谈业务,合作代理。让我们携手奋进,共创辉煌。

Molding silicone rubber

Usage:

For toy gifts and craftwork gift, products with complex fine details, and made in pouring way.

Description:

HY-638# silicon rubber is mainly used for toy gifts and craftwork gifts with the advantages of good tensile strength, high tear strength, high temperature resistance, high duplication times and repeated use, etc. It is suitable for small products or fine and precision products which is difficult to demould. This silicone rubber is one of the products with the highest use level in the production of craftwork gifts and the shrinkage is up to 2‰.

Silicon rubber for mold making applications:

Silicon rubber for molding making is primarily intended for poly resin crafts, PU crafts, PU resin crafts ,gypsum crafts ,unsaturated resin crafts, lighting and candles crafts ,plastic toy , stationery gifts crafts industry, a large statue Buddha, relievo furniture, furniture decorative materials, statues Buddha, artifacts copied, building decoration materials, large-scale cement mold, artificial fossils Factory, Europe component factory, simulation landscapes, animals and plants sculpture, sandstone crafts and so on.

Silicon rubber for mold making features description:

Silicon rubber for mold making is white or red flowing liquid with general hardness of 22-50A°after curing. Molding silicon rubber is a kind elastic silicon rubber mold which features with resistance to deformation, high-temperature, acid-alkali and expansion as well as high reproduction times, good tensile strength, tear strength and elongation.

Silicon rubber for mold making operations:

If the customer wants to make large products and large size molds, the mold should be made of silicon rubber with high hardness. On the contrary,if the mold with fine and precision patterns, it should be made of silicon with low hardness. The amount of the curing agent depends on the actual requirements of the customer. If molds requiring fast drying and demold, more curing agent is needed; contrarily,if molds requiring slower drying and demold, less curing agent is needed.

(Note: our company does not recommend you to add silicone oil. If a special soft silicon mold or fine detailed and complex patterns products are required, 5%-10% silicone oil can be added to soften the mold for easy demould.)

Frequently asked questions of molding silicone rubber

Why does the silicone rubber mold have few molding times?

The silicone rubber mold has few molding times is due to follwoing reasons: adding too much silicone oil which will destroy the molecular of silicone rubber; making the mold for small and fine detailed products with higher hardness silicone rubber which is easy to break; making the mold for large products with soft silicone rubber which will reduce the tensile and tear strength of the mold, and the mold will have deformation.Thus, we should take the proper silicone rubber to make the mold for suitable products.

相关产品推荐

-

AB双组份模具硅橡胶

AB双组份模具硅橡胶

-

仿道康宁模具硅胶 仿道康宁模具液体硅胶 仿道康宁模具液体硅胶矽胶

仿道康宁模具硅胶 仿道康宁模具液体硅胶 仿道康宁模具液体硅胶矽胶

-

仿日本信越电子灌封胶 仿日本信越电子灌封硅橡胶 日本信越电子灌封硅橡胶电子胶 日本信越电子灌封硅橡胶 电子胶

仿日本信越电子灌封胶 仿日本信越电子灌封硅橡胶 日本信越电子灌封硅橡胶电子胶 日本信越电子灌封硅橡胶 电子胶

-

硅橡胶矽胶真空袋 硅橡胶矽胶液体硅胶真空袋

硅橡胶矽胶真空袋 硅橡胶矽胶液体硅胶真空袋

-

移印矽利康 移印硅胶矽利康 移印液体硅胶矽利康

移印矽利康 移印硅胶矽利康 移印液体硅胶矽利康

-

933#移印硅胶瓦克623 933移印硅胶仿瓦克623 933移印液体硅胶仿瓦克623

933#移印硅胶瓦克623 933移印硅胶仿瓦克623 933移印液体硅胶仿瓦克623

-

游艇轮船真空袋模具硅胶 游艇轮船真空袋模具硅胶橡胶 游艇轮船真空袋模具硅胶橡胶矽胶

游艇轮船真空袋模具硅胶 游艇轮船真空袋模具硅胶橡胶 游艇轮船真空袋模具硅胶橡胶矽胶

-

船舶真空袋模具硅胶矽胶 船舶真空袋模具液体硅胶矽胶 船舶真空袋模具液体硅橡胶

船舶真空袋模具硅胶矽胶 船舶真空袋模具液体硅胶矽胶 船舶真空袋模具液体硅橡胶

-

深圳红叶硅胶厂供应缩合型液态硅胶

深圳红叶硅胶厂供应缩合型液态硅胶

-

深圳红叶硅胶厂供应半透明模具硅橡胶

深圳红叶硅胶厂供应半透明模具硅橡胶