日本三之星-MAXSTAR WEDGE-三角带

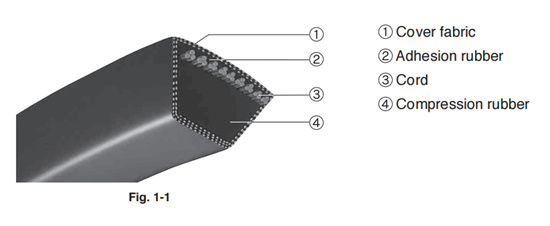

Belt construction

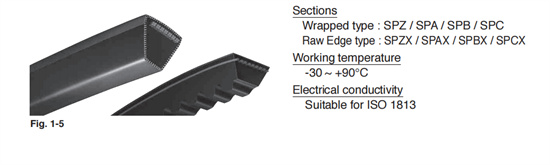

Wrapped V-Belts

"Wrapped" means that the V-Belt core is protedted by cover fabric

made of cotton or polyester.

The cover fabric is coated with rubber to reinforce the wear resistance.

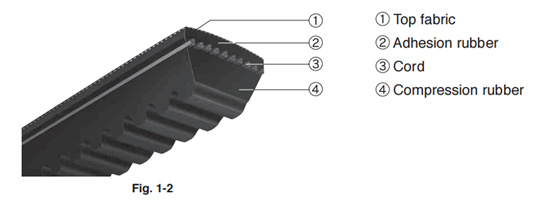

Raw Edge V-Belts

Raw Edge V-Belts have no fabric on the belt sides.

The special rubber compound ensures greater wear resistance

than Wrapped V-Belts.

Classical V-Belts for JIS K 6323

Classical V-Belts are most widely used power transmission belts.

Economical and easily obtained for replacement.

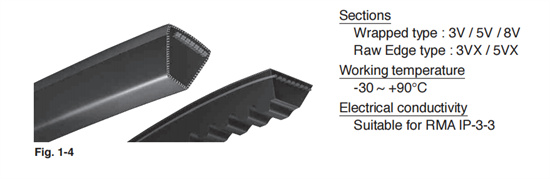

Maxstar Wedge V-Belts for RMA / MPTA

Maxstar Wedge V-Belts have double power transmission capacity of classical V-Belts

due to greater wedge effect. It features high speed transmission, energy saving, and

compact design.

Narrow V-Belts for DIN 7753 / ISO 4184

Narrow V-Belts enable space saving, high speed drive, and reduce the cost of

operating and maintenance.

It features oil / heat resistance and electrical conductivity.

Multi V-Belts

Multi V-Belts are made up of two or more standard V-Belts connected together

at the top of the belts. Multi V-Belts have the advantage of preventing the belts

from turning over or getting thrown off the drive even when belt vibration occures.

Double V-Belts

Double V-Belts are recommended for serpentine drives where the power must be

transmitted by both the top and the bottom of the belts.

Excellent flfl exibility in both directions.

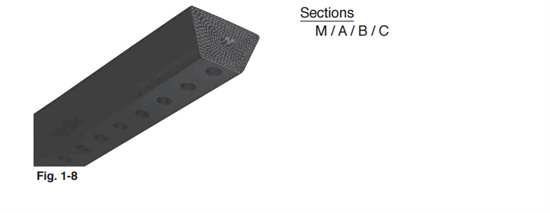

Perforated open-end V-Belts

Perforated open-end V-Belts are designed for easy installation with metal fastners

and a screwdriver.

These belts are recommended for temporary use or when installation of the

standard V-Belts is diffifi cult.