厂商 :山东双鹤机械制造

山东 德州市- 主营产品:

- 饲料机械

- 牧草机械

- 化工设备

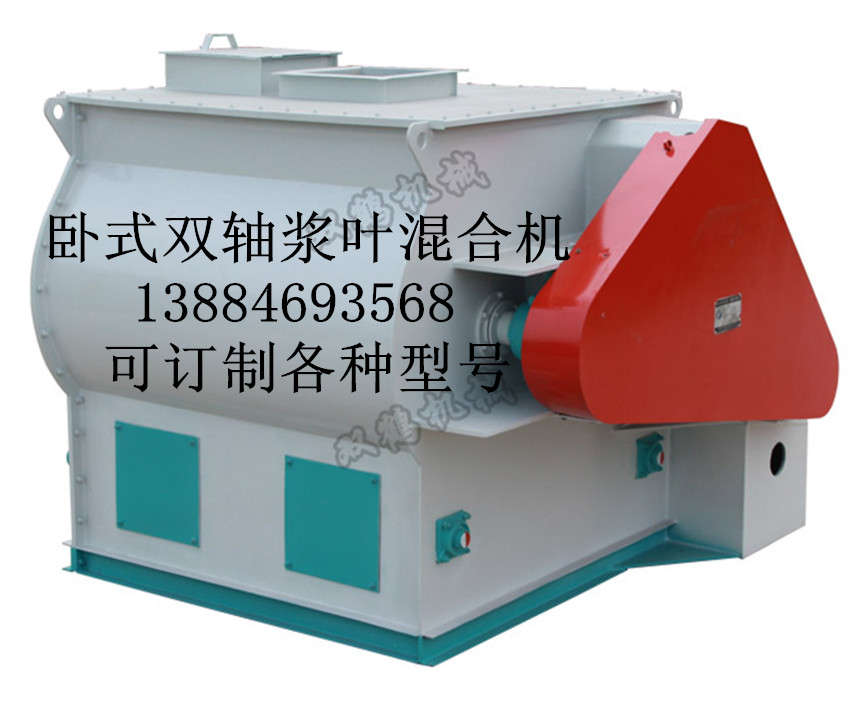

HHSJ系列双轴桨叶混合机

HHSJ Series Double Shaft Paddle Mixer

1、用途及特点

1. Usage And Characteristics

HHSJ系列双轴桨叶式高效混合机广泛用于饲料、粮食、化工、医药、农药等行业中粉状、颗粒状、片状、杂状及粘稠状物料的混合。

HHSJ series double shaft paddle type mixer is widely used in feed, grain, chemical, pharmaceutical, pesticide industries for the powder, granular mixing and flaky, miscellaneous and viscous material mixture.

2、工作原理

2. Working Principle

该机配备两个旋转方向相反的转子,转子由转子轴、支杆、桨叶组成,支杆与转子轴“十字”相交,桨叶成特殊角度焊在支杆上。转子上的桨叶带动物料一方面沿着机槽内壁旋转并向一端移动,另一方面带动物料左右翻动;在两转子的交叉重叠处,形成了一个失重区,在此区域内,不论物料的形状、大小和密度如何,都能使物料上浮,处于瞬间失重状态,使物料在机槽内形成连续循环翻动,相互交错剪切,从而达到快速混合均匀的效果。

The machine has two rotors whose rotating direction is on the contrary, the rotor consists of the shaft, supporting rod and paddle, supporting rod cross in the shaft, the paddle is welded on the supporting rod at a certain angle.

On the one hand, the paddles push the raw materials to move towards the other end of mixer along inner wall of closed tough, on the other hand, the paddles also promote the raw materials to stir around, therefore, there is zero gravity zone to be shaped between two rotors crossed overlap, in the zero gravity zone the raw material can flow up and instantly lose gravity to make continuous circular stir and commutative cutting for realizing the fast homogeneous mixing whatever the raw material shape,size and density is.

3、主要技术参数

3. Main Data Sheet

|

Model |

HHSJ4 |

HHSJ2 |

HHSJ1 |

HHSJ0.5 |

|

Volume(m3) |

4.0 |

2.0 |

1.0 |

0.5 |

|

Capacity/batch(kg) |

2000 |

1000 |

500 |

250 |

|

Mixed time(s) |

90-120 |

|||

|

Mixed uniformity(CV≤%) |

5 |

5 |

5 |

5 |

|

Main power(kw) |

30 |

18.5 |

11 |

5.5 |

|

Rotor Speed(r/min) |

22 |

25 |

30 |

41 |

HHSJ系列双轴桨叶混合机

HHSJ Series Double Shaft Paddle Mixer

1、用途及特点

1. Usage And Characteristics

HHSJ系列双轴桨叶式高效混合机广泛用于饲料、粮食、化工、医药、农药等行业中粉状、颗粒状、片状、杂状及粘稠状物料的混合。

HHSJ series double shaft paddle type mixer is widely used in feed, grain, chemical, pharmaceutical, pesticide industries for the powder, granular mixing and flaky, miscellaneous and viscous material mixture.

2、工作原理

2. Working Principle

该机配备两个旋转方向相反的转子,转子由转子轴、支杆、桨叶组成,支杆与转子轴“十字”相交,桨叶成特殊角度焊在支杆上。转子上的桨叶带动物料一方面沿着机槽内壁旋转并向一端移动,另一方面带动物料左右翻动;在两转子的交叉重叠处,形成了一个失重区,在此区域内,不论物料的形状、大小和密度如何,都能使物料上浮,处于瞬间失重状态,使物料在机槽内形成连续循环翻动,相互交错剪切,从而达到快速混合均匀的效果。

The machine has two rotors whose rotating direction is on the contrary, the rotor consists of the shaft, supporting rod and paddle, supporting rod cross in the shaft, the paddle is welded on the supporting rod at a certain angle.

On the one hand, the paddles push the raw materials to move towards the other end of mixer along inner wall of closed tough, on the other hand, the paddles also promote the raw materials to stir around, therefore, there is zero gravity zone to be shaped between two rotors crossed overlap, in the zero gravity zone the raw material can flow up and instantly lose gravity to make continuous circular stir and commutative cutting for realizing the fast homogeneous mixing whatever the raw material shape,size and density is.

3、主要技术参数

3. Main Data Sheet

|

Model |

HHSJ4 |

HHSJ2 |

HHSJ1 |

HHSJ0.5 |

|

Volume(m3) |

4.0 |

2.0 |

1.0 |

0.5 |

|

Capacity/batch(kg) |

2000 |

1000 |

500 |

250 |

|

Mixed time(s) |

90-120 |

|||

|

Mixed uniformity(CV≤%) |

5 |

5 |

5 |

5 |

|

Main power(kw) |

30 |

18.5 |

11 |

5.5 |

|

Rotor Speed(r/min) |

22 |

25 |

30 |

41 |

HHSJ系列双轴桨叶混合机

HHSJ Series Double Shaft Paddle Mixer

1、用途及特点

1. Usage And Characteristics

HHSJ系列双轴桨叶式高效混合机广泛用于饲料、粮食、化工、医药、农药等行业中粉状、颗粒状、片状、杂状及粘稠状物料的混合。

HHSJ series double shaft paddle type mixer is widely used in feed, grain, chemical, pharmaceutical, pesticide industries for the powder, granular mixing and flaky, miscellaneous and viscous material mixture.

2、工作原理

2. Working Principle

该机配备两个旋转方向相反的转子,转子由转子轴、支杆、桨叶组成,支杆与转子轴“十字”相交,桨叶成特殊角度焊在支杆上。转子上的桨叶带动物料一方面沿着机槽内壁旋转并向一端移动,另一方面带动物料左右翻动;在两转子的交叉重叠处,形成了一个失重区,在此区域内,不论物料的形状、大小和密度如何,都能使物料上浮,处于瞬间失重状态,使物料在机槽内形成连续循环翻动,相互交错剪切,从而达到快速混合均匀的效果。

The machine has two rotors whose rotating direction is on the contrary, the rotor consists of the shaft, supporting rod and paddle, supporting rod cross in the shaft, the paddle is welded on the supporting rod at a certain angle.

On the one hand, the paddles push the raw materials to move towards the other end of mixer along inner wall of closed tough, on the other hand, the paddles also promote the raw materials to stir around, therefore, there is zero gravity zone to be shaped between two rotors crossed overlap, in the zero gravity zone the raw material can flow up and instantly lose gravity to make continuous circular stir and commutative cutting for realizing the fast homogeneous mixing whatever the raw material shape,size and density is.

3、主要技术参数

3. Main Data Sheet

|

Model |

HHSJ4 |

HHSJ2 |

HHSJ1 |

HHSJ0.5 |

|

Volume(m3) |

4.0 |

2.0 |

1.0 |

0.5 |

|

Capacity/batch(kg) |

2000 |

1000 |

500 |

250 |

|

Mixed time(s) |

90-120 |

|||

|

Mixed uniformity(CV≤%) |

5 |

5 |

5 |

5 |

|

Main power(kw) |

30 |

18.5 |

11 |

5.5 |

|

Rotor Speed(r/min) |

22 |

25 |

30 |

41 |

-

供应水滴式粉碎机鸡饲料粉碎机双鹤 双鹤供应水滴式粉碎机鸡饲料粉碎机 双鹤供应水滴式粉碎机鸡饲料粉碎机

供应水滴式粉碎机鸡饲料粉碎机双鹤 双鹤供应水滴式粉碎机鸡饲料粉碎机 双鹤供应水滴式粉碎机鸡饲料粉碎机

-

山东双鹤时产1-2吨畜禽颗粒饲料 山东时产12吨畜禽颗粒饲料生产线

山东双鹤时产1-2吨畜禽颗粒饲料 山东时产12吨畜禽颗粒饲料生产线

-

低能耗高产量省时省力 低能耗高产量的双鹤水滴式粉碎机 双鹤水滴式粉碎机低能耗高产量

低能耗高产量省时省力 低能耗高产量的双鹤水滴式粉碎机 双鹤水滴式粉碎机低能耗高产量

-

木材颗粒机双鹤生物质颗粒机助你发 双鹤生物质颗粒机木材颗粒机助你发 双鹤生质颗粒机木材颗粒机助你发财

木材颗粒机双鹤生物质颗粒机助你发 双鹤生物质颗粒机木材颗粒机助你发 双鹤生质颗粒机木材颗粒机助你发财

-

粉碎玉米芯的专用设备双鹤水滴式粉 粉碎玉米芯的专用设备水滴式粉碎机

粉碎玉米芯的专用设备双鹤水滴式粉 粉碎玉米芯的专用设备水滴式粉碎机

-

什么牌的混合机好用山东双鹤混合机

什么牌的混合机好用山东双鹤混合机

-

青贮圆草捆全自动打捆机山东双鹤 青贮圆草捆全自动打捆机双鹤批发

青贮圆草捆全自动打捆机山东双鹤 青贮圆草捆全自动打捆机双鹤批发

-

猫砂生产设备双鹤机械厂家直供交钥 猫砂生产设备厂家直供交钥匙双鹤机 猫砂生产设备双鹤厂家直供交钥匙

猫砂生产设备双鹤机械厂家直供交钥 猫砂生产设备厂家直供交钥匙双鹤机 猫砂生产设备双鹤厂家直供交钥匙

-

贵州双鹤饲料颗粒机厂家直销哪家好 贵州双鹤饲料颗粒机厂家直销放心省 贵州双鹤饲料颗粒机厂家直销哪家强

贵州双鹤饲料颗粒机厂家直销哪家好 贵州双鹤饲料颗粒机厂家直销放心省 贵州双鹤饲料颗粒机厂家直销哪家强

-

双鹤470牛羊饲料颗粒机养殖专用 470牛羊饲料颗粒机双鹤直销 双鹤直销470牛羊饲料颗粒机

双鹤470牛羊饲料颗粒机养殖专用 470牛羊饲料颗粒机双鹤直销 双鹤直销470牛羊饲料颗粒机