厂商 :东莞市新塑塑胶机械有限公司

广东 东莞- 主营产品:

- 缠绕膜流延机

- 缠绕膜挤出机

- 拉伸膜流延机

全自动双层三层共挤拉伸膜生产线WT-55/75x1250MM

Automatic double three layer stretch film production line WT-55/75x1250MM

本机组以LLDPE(线性低密度聚乙烯)为主要原料,采用几种不同牌号的树脂,通过流延、挤出而生产出具有自粘性,单面性、双面粘的单层、双层、三层、五层拉伸缠绕膜或用于食品包装用的PE保鲜膜。

The unit to LLDPE (linear low density polyethylene) as the main raw material by several different grades of resin, by casting, extrusion and produce self-adhesive, single-sided, double-sided sticky single, double, three layer, five layer tensile stretch film or for food packaging with the PE fresh keeping film.

|

型号 |

WT-55/75x1250MM全自动双层三层共挤拉伸膜生产线 Automatic double three layer stretch film production line WT-55/75x1250MM |

|

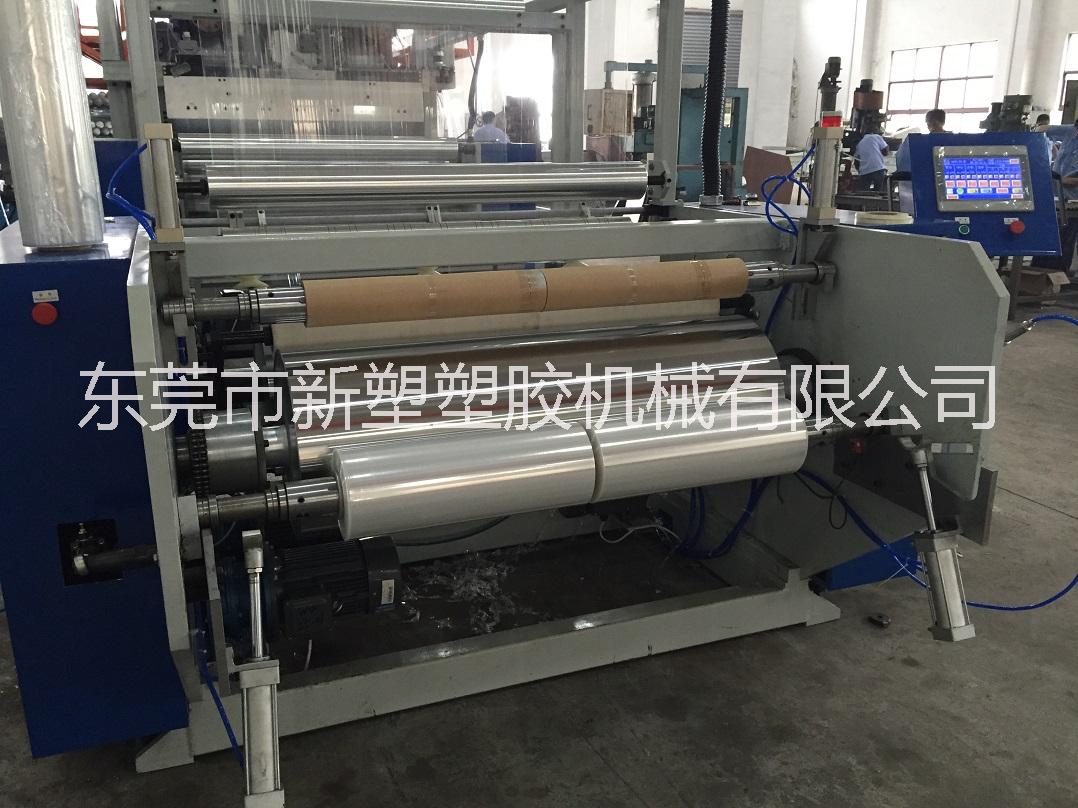

缠绕膜机结构 Winding film machine structure |

挤出机、三通、模具、钢结构架、冷却辊、收卷装置。 Extruding machine, three pass, mould, steel structure frame, cooling roller, rolling device. |

|

适用范围: Scope of application: |

结合多种特性原料,可生产高品质缠绕膜。 Combined with a variety of characteristics of raw materials, can produce high quality winding film.

|

|

适用材料 Applicable material |

HDPE , LDPE , LLDPE , 二级回料 , 填充料 。 HDPE , LDPE , LLDPE , Two stage feed back, filling material. |

|

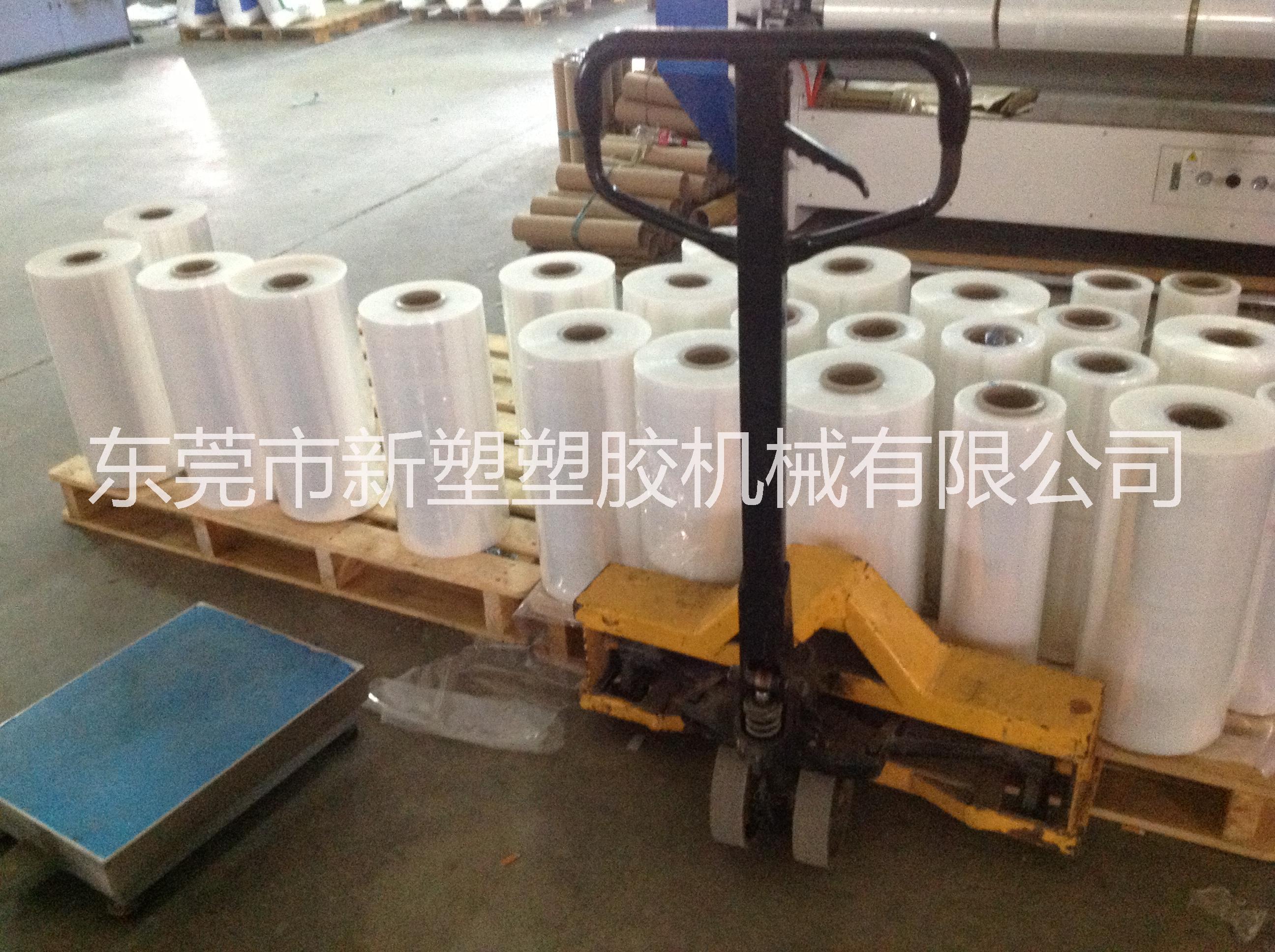

输出成品 Output of finished products |

缠绕膜 Wrapping film |

|

產能 Production capacity |

Capacity per hour 100kg-120kg/h |

专家点评:

本机组以LLDPE(线性低密度聚乙烯)为主要原料,采用几种不同牌号的树脂,通过流延、挤出而生产出具有自粘性,单面性、双面粘的单层、双层、三层拉伸缠绕膜或用于食品包装用的PE保鲜膜。

该缠绕膜机组具有全自动柔性收换卷功能,即自动断料、自动收换卷,全过程PLC控制,安全可靠,无误动作。其自动断料刀采用的磨齿由专业刀具厂制造。其收料辊独立于变频器控制,调整速度快,有效保证收料辊的张力均衡,收料平整,且省电。整机操作方便,速度、温度实时监控;抗干扰能力强,随着变频器、温度控制器稳定性提高,正常工作寿命大大延长。人机交互界面设计人性化,信息丰富而清晰,客户可根据个人操作习惯和不同使用条件自行设置整车操控性,充分满足客户的个性化需求。

该机组采用国外先进主机摆动出膜方式,从而使产品收卷更紧,更加均匀平整,可与进口拉伸缠绕膜相媲美。

Expert comments:

The unit to LLDPE (linear low density polyethylene) as the main raw material by several different grades of resin, by casting, extrusion and produce self-adhesive, single-sided, double-sided sticky single-layer, double-layer, triple layer stretch film or for food packaging with the PE fresh keeping film.

The winding film unit has the function of automatic flexible winding and winding, that is, automatic cutting, automatic coiling, whole process PLC control, safe and reliable, and no mistake action. Its automatic cutting tool used in the grinding of the professional cutter factory. The material receiving roller is independent of the frequency converter control, and the adjustment speed is fast, which effectively guarantees the tension balance of the material receiving roller, the material receiving level, and the power saving. The whole machine has the advantages of convenient operation, real-time monitoring of speed and temperature, strong anti-interference ability, and the stability of the frequency converter and temperature controller is improved, and the normal working life is prolonged. Human computer interaction interface design, information rich and clear, customers can use their own operating habits and different conditions to set the vehicle handling, fully meet the individual needs of customers.

The unit using foreign advanced host sway way out of the film, so that the product to make plastic products better, puncture resistance stronger, coiling tighter, more uniform and smooth, and import stretch wrap film comparable, more competitive market.

产品亮点:

1、采用国外先进主机摆动出膜方式,从而使产品塑化更好,抗刺穿性更强、收卷更紧,更加均匀平整,可与进口拉伸缠绕膜相媲美,市场竞争力更强。

2、最大产量:60—220公斤/小时

3、整个生产过程采用进口PLC控制系统控制,实现生产智能化。随意调整所需产品宽度,自动断料、自动换纸筒,采用“瓦片式”气胀轴麽擦式自动收卷,柔性换卷,安全可靠,无误动作。

4、采用双回路冷却系统,配合微电脑模控制机精确控制冷却辊温度,使膜料平整、厚薄均匀。

5、38CRMOALA优质合金钢螺杆,内外表面氮化处理。配合进口静态混合器,确使料粒融化,色泽均匀,挤出量大为提高。

6、主控制电箱:独立设计,与主机分开摆放。操作方便,速度、温度时实监控直观;抗干扰能力特强,变频器、温度控制器稳定性提高,正常工作寿命延长。

7、温控采用先进自动控制系统,可准确控制塑化过程、调整膜料厚度和平整性。

8、模具:采用进口模具,衣架式设计,温区增加至7段,模头中间为插入式发热管,并全封闭,航空杆插座式接头。

9、模间隙调校:采用推式细牙螺丝调整,调整范围:0.013-0.5mm。

10、采用先进的扭矩马达及变频调速牵引,四轴自动张力控制,自由调节出膜的速度和宽度。

Product highlights

1, the use of advanced foreign host swing out of the film, so that the product better, better resistance to puncture, close to a more compact, more uniform and smooth, can be comparable with the imported stretch wrap film, the market is more competitive.

2, maximum output: 60- 220 kg / h

3, the entire production process using imported PLC control system control, to achieve the production of intelligent. Random adjustment required product width, automatic cutting, automatic change of tube, using "tiles" inflatable shaft friction type automatic winding, flexible change volume, safe and reliable, without misoperation.

4, the double loop cooling system, with the mode of the microcomputer control precision machine control cooling and temperature, the membrane material smooth, uniform thickness.

5, 38CRMOALA high quality alloy steel screw, internal and external surface nitriding treatment. With imported static mixer, it does make the material melt, the color is even, the extrusion quantity is greatly improved.

6, the main control box: independent design, and the host to separate. The operation is convenient, the speed and temperature are real monitoring and control, the anti-interference ability is very strong, the frequency converter and the temperature controller stability is improved, and the normal working life is prolonged.

7, the temperature control using advanced automatic control system, can accurately control the process of plastic, adjust the thickness of the film material and the whole.

8, mold: the use of imported mold, clothes rack type design, temperature area increased to 7, the middle of the mold is inserted into the heating pipe, and the whole closed, the aviation rod socket connector.

9, die gap adjustment: the push type fine teeth screw adjustment, adjustment range: 0.013-0.5mm.

10, the use of advanced torque motor and variable frequency speed control, four axis automatic tension control, free to adjust the speed and width of the film.

选配配置:

1 .负压真空箱

2..熔体增压泵及PID控制系统全自动模具

3.微电脑及触摸屏精准控温

4.全自动化机械手换卷及上卷

5.冷水机和冷却塔

6.胶水泵

Optional:

1.Sub-atmospheric Vacuum Pump.

2.Melting Gear Pump and PID Control System.

3.Accurate Touchable Screen Temperature Controller.

4.Robot Hands for Roll-change and Roll-rewinding Aromatically

5.Water Cooling Chiller and Cooling tower

6.Glue pump

主要技术参数 Main Technical Parameters

|

型号 Model |

WT-55/75/X1250 |

|

层数 Layers |

两层或三层 |

|

螺杆直径 Screw Diameter |

55/75mm |

|

螺杆长径比 Screw L/D |

1:30 |

|

螺杆转速 Screw speed |

20-150rpm |

|

制品宽度 Width |

1000mm/2*500mm |

|

总功率 Total Power |

100KW |

|

产品厚度 Thickness |

0.012-0.05mm |

|

生产能力 Capacity |

80-140kg/h |

|

膜层结构 Layer Structure |

AB/ABC |

|

整机重量 Total Weight |

7T |

|

外形尺寸 Dimension |

(L)7500*(W)3500*(H)3200 |