厂商 :苏州佰齐机械有限公司

江苏 苏州市- 主营产品:

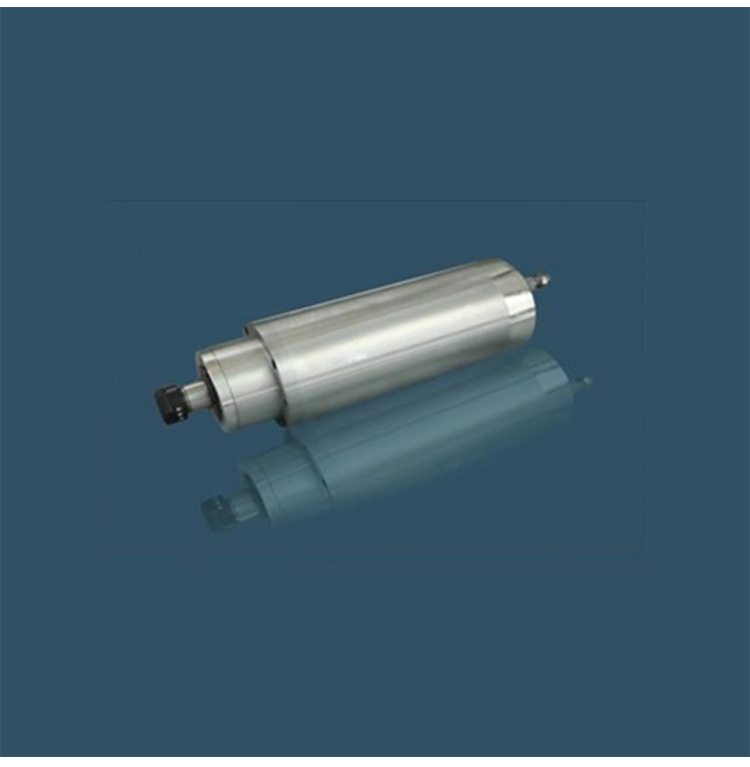

- 风冷电主轴

- 自动换刀电主轴

- 直结式机械主轴

承接各型号电主轴的检测与维修。

各种风冷电主轴、水冷电主轴,精雕机主轴,木工机主轴,石材机主轴,加工中心主轴。

承诺收到货后1-2天内修好返回。

主轴的使用注意事项:notes on using the spindles

1 严格按外形图指示位置装夹电主轴:电主轴的装夹位置应避开轴承位,在前后轴承之间的定子部位夹紧,夹紧力不宜过大,电主轴装入机座内不得松动。

Please clamping motorized spindle in accordance with the outline drawing indicating location strictly. The clamping position of spindle should avoid bearing , the stator parts which between the front and rear bearing need to be clamped, clamping force should not be too large, spindle should not be loosed when loaded within the frame.

2除频率及功能匹配外,变频器的额定输出电压要和电主轴匹配,变频器的额定电流要比电主轴的额定电流略大(一般是1.5-2倍)。严格按电主轴V-F曲线设置变频器各项参数,如设置不正确,会烧毁电主轴。

In addition to matching the frequency and functions, the inverter rated output voltage need to match with electric spindle’s. The rated current of the inverter rated current are slightly larger than the spindle (usually 1.5-2 times). Please set the parameters in strict accordance with the drive spindle VF curve. If the settings are incorrect, it will burn the spindle.

3严禁在无冷却的条件下使用水冷电主轴,冷却水量按1升/千瓦分钟计算,冷却水量最低流量不小于5升/分钟,冷却水管不能有急弯堵塞现象,且水嘴连接必须可靠,不泄露。

Prohibited using water-cooled spindle under the conditions in the absence of water-cooled. If the cooling water is count by at 1 liter / kW minute, the minimum amount of cooling water flow rate is not less than 5 l / min.The cooling water pipe can not have sharp bends clogging, and tap connections must be reliable, not leak .

4冷却液必须清洁,无油腻,温度控制在5-3℃。若环境温度高于30℃,冷却介质必须强制制冷。精密加工机床要求冷却液恒温20±2℃。

Coolant must be clean, non-greasy, and temperature controlled should be at 5-3 ℃. If the ambient temperature is above 30 ℃, the cooling medium must be forced cooling. Precision machine tools required coolant temperature 20 ± 2 ℃.

5主轴通气必须确保洁净、干燥。空压机要经常排水,在使用气封及其它通气情况下,气源须经油水分离器、干燥过滤器方可使用,气封气压在0.2-0.25Mpa,过滤精度5μm,气缸及换刀除尘气压在0.45-0.65Mpa,

否则会造成轴承及气缸内部元件的损坏。

Ventilation shaft should be clean and dry. The air compressor need to drain often .In the use of ventilation air sealing and other cases, the gas supply shall be oil-water separator, filter drier before use. The air sealing pressure should be at 0.2-0.25Mpa, filtering accuracy 5μm, cylinders and dust removal tool pressure in the 0.45-0.65Mpa,

Otherwise it will cause bearings and cylinder damage internal components.

6、电主轴装夹刀具时,不能使用蛮力,必须将筒夹、压帽、刀柄、内锥孔及轴端螺纹处清洗干净,以免影响精度,造成内锥孔及筒夹锥面磨损,转轴螺纹和压帽滑扣,刀具插入筒夹必须大于15毫米。

When clamping tool, you can not use brute force. And the collet, pressure cap, handle, bore taper and the threads,all of these need to be cleaned, so as not to affect the accuracy, resulting taper and collet cone wear, slidering shaft thread and pressure cap, and tool insert collet must be greater than 15 mm.

7、主轴压帽是经过动平衡修正过的零件,请勿随意更换。主轴运转前,切削刀具必须被确定锁紧或锁刀具用的压帽必须被取下。

Spindle pressure cap is a corrected part through dynamic balancing .Please do not replace it optionally. Before the spindle running , please be sure that the cutting tool are locked or the pressure cap must be removed

8每天开始工作时,电主轴要从低速到高速运行的原则,逐步升速预热,当达到所需转速且空载运转平稳、温度冷却后再进行加工,这样才能保证较好的加工精度及使用寿命。电主轴在长期保存过程中应至少在一星期内开机低速运行15-30分钟。

In accordance with the speed operation principle from low to high, spindle need to increases the speed gradually in the aim of making the bearing warm-up when begin to work each time. When achieving the desired speed, smooth no-load operation and temperature, you can carry on the processing , so as to ensure better processing accuracy and the use of life. Spindle in the long-term preservation process should start at low speed for 15-30 minutes a week at least.

9、电主轴必须按指示方向运转。

The direction of the spindle must be running as instruction.

10、使用工件切削液时,一定要将切削液冲在刀具切削部位,只有这样才能起到对刀具和工件的冷却作用,严谨将切削液冲在压帽及以上位置。

Please be sure to punch cutting fluid in cutting tool parts. Only in this way, it can play on the cooling effect of the tool and the workpiece. No cutting fluid splash the pressure cap and the above locations.

11、严禁使用刀刃磨损的刀具进行加工。刀具磨损后仍继续使用,会加大电主轴轴向力,导致轴承受损,而且还会影响雕刻的精度及效果。

Do not use the blade worn tool for processing. Continued to use of tool wear, spindle axial force will be increase, leading to bearing damage, but will also affect the accuracy and effectiveness of engraving.

12、卸刀时严谨敲打筒夹及刀头。运输、保管及使用中严谨磕碰、敲击、撞击电主轴轴端。

No beating the collet and cutter head in the process of unloading knife. No bumping, peening, striking the shaft end during the process of transporting, storing and using.

13、使用水(油)冷机进行冷却的用户温度必须控制在22℃-25℃。

The temperature must be controlled during 22 ℃ -25 ℃ when you use water cooler or oil cooler for cooling.

14、一日12小时以上连续加工,宜让电主轴停机1小时以上,以便恢复机械疲劳,从而延长使用寿命。

Continuous processing more than 12 hours a day, you should let motorized spindle be in halt mode more than1 hour in order to restore the mechanical fatigue, and prolong service life

15、电主轴在每次使用完毕后,应即时将切削液自自主轴上清除干净,并以防锈油擦拭主轴内孔及刀把柄部,以避免生锈。再次使用须清除防锈油。

After using the spindle each time, cutting fluid should be immediately cleaned from the independent axis, and wipe anti-rust oil on spindle bore and knife handle portion to avoid rusting. Clear the anti-rust oil when it is used next time.

16、主轴异常或故障时,应及时与主轴制造商联系,请勿自行拆解主轴,否则责任自负。

Spindle is abnormal or out of order, you should contact the manufacturer of the spindle promptly. Do not disassemble, otherwise at your own risk.