厂商 :深圳市红叶杰科技有限公司

广东省 深圳市- 主营产品:

- 硅胶

- 硅橡胶

- 液体硅胶

联系电话 :18938867511

商品详细描述

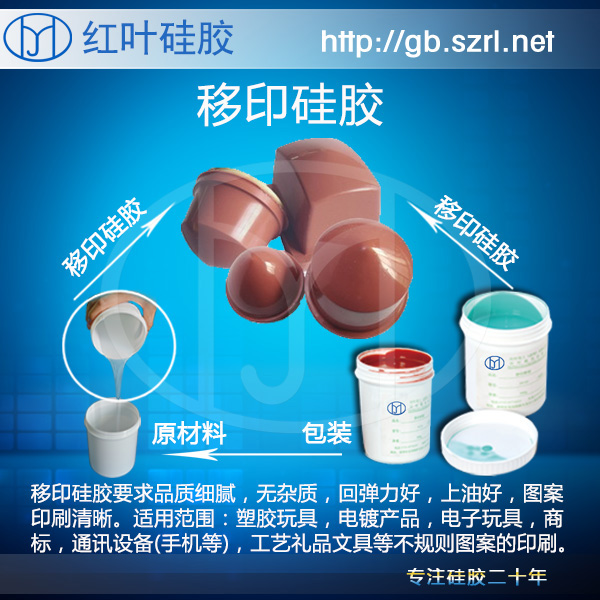

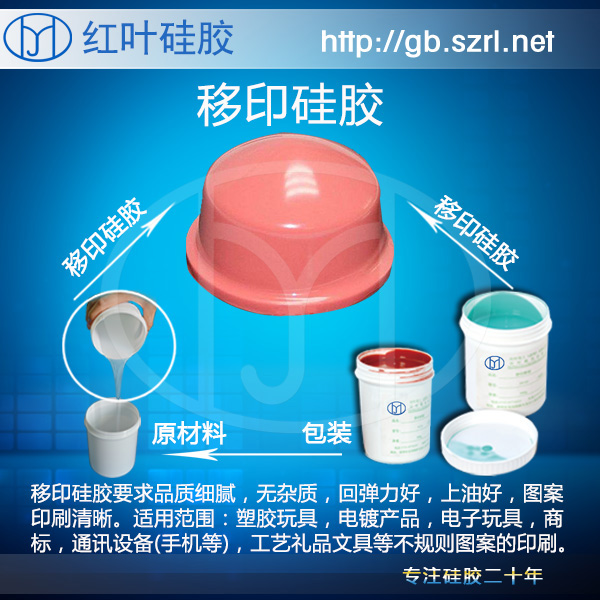

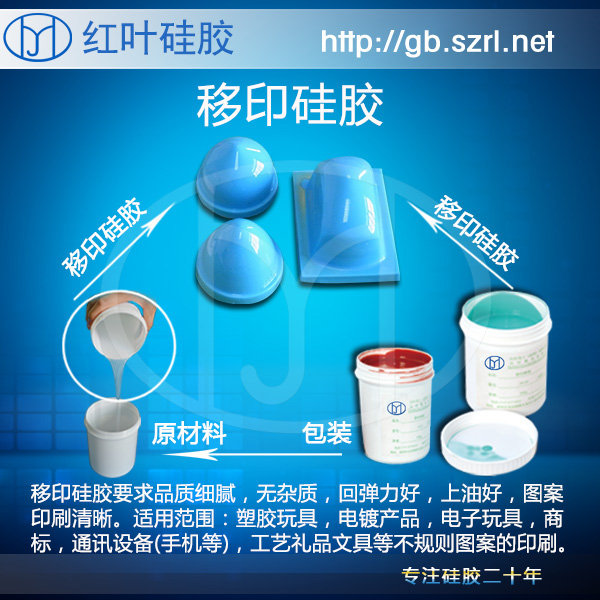

供应 pritingsilicone、移印硅胶、移印胶 pritingsiliconepriting silicone,pad pritig silicon

pad printing silicon pritingsilicone、移印硅胶、移印胶

1. Wash and clean molds with detergents, dry the molds and use an air gun if necessary, and apply a film of mold release.

2. Determine the normal proportion of pad printing silicon and silicon oil on the basis of customer requirements. Add more silicon oils if a larger area of printed pattern and therefore soft rubber head is needed by the customer. Otherwise, add no or less silicon oil for better hardness. For normal pad printing rubber head, hardness between 15 A°--25A°will be appropriate. If excessive amount of silicon oil is added, the number of printing will be limited by an extremely soft rubber head, and the molecular weight of silicon of however supreme quality will be destroyed by silicon oil, and therefore, the phenomenon of compromised resistance to abrasion, solvent and aging.

3. The normal proportion is as follows: 100g silicon admixed with 30g silicon oil for a hardness of 20 A° will be suitable for pad printing for alloy toy cars and products with small patterns and contact area. If larger pressure contact surface or soft rubber head is required, the silicon and silicon oil proportion can be adjusted to 100:50, 100:80 and so on. Remember, the more silicon oil is added, the softer the rubber head will be, and the number of pad printing, resistance to abrasion and solvent will be undermined, and hence, heightened cost and more material waste.

4. Admixture amount of curing agent and chemical reaction of silicon: e.g., mix 100g of silicon with 50g of silicon oil, after they are sufficiently and evenly mixed, add curing agent as per 2% of the total weight of silicon and silicon oil, mix again for 2-3 minutes before exhausting. Generally exhausting duration can not exceed 10 minutes; otherwise, the silicon will harden quickly to affect the quality of molding.

5. Admixture amount of curing agent and silicon reaction:

5.1. Added with 1% of curing agent, silicon can still flow within 2.5 hours, mold can be released in 6-8 hours.

5.2. Added with 2% of curing agent, silicon can still flow within 50 minutes to 1 hour, mold can be released in 2-3 hours.

5.3. Added with 3% of curing agent, silicon can still flow within 28-30 minutes, mold can be released in 1.5-2 hours

5.4. Added with 4% of curing agent, silicon can still flow within 10-15 minutes, mold can be released in 1-1.5 hours

5.5. Curing agent reaction rate is related with weather and temperature. Under 25 degree, they can be added according to the instruction or at double amount in winter or under subzero temperature.

(Note: curing agent can not be added above the 4% maximum level and the normal proportion is 2%. If more than 4% is applied, the silicon will condensate too fast for normal usage).

Above is the mixing data for silicon and curing agent, the precise result of hundreds of times of our experiments. Provided that you arrange production according to our instruction, you are sure to manufacture first class products and maximize your profit – this is not only the need of, but also our responsibility for and a satisfactory answer to our customers. We may not be the first, but we will try to be the best. The customers need is what we pursue !

pad printing silicon pritingsilicone、移印硅胶、移印胶

1. Wash and clean molds with detergents, dry the molds and use an air gun if necessary, and apply a film of mold release.

2. Determine the normal proportion of pad printing silicon and silicon oil on the basis of customer requirements. Add more silicon oils if a larger area of printed pattern and therefore soft rubber head is needed by the customer. Otherwise, add no or less silicon oil for better hardness. For normal pad printing rubber head, hardness between 15 A°--25A°will be appropriate. If excessive amount of silicon oil is added, the number of printing will be limited by an extremely soft rubber head, and the molecular weight of silicon of however supreme quality will be destroyed by silicon oil, and therefore, the phenomenon of compromised resistance to abrasion, solvent and aging.

3. The normal proportion is as follows: 100g silicon admixed with 30g silicon oil for a hardness of 20 A° will be suitable for pad printing for alloy toy cars and products with small patterns and contact area. If larger pressure contact surface or soft rubber head is required, the silicon and silicon oil proportion can be adjusted to 100:50, 100:80 and so on. Remember, the more silicon oil is added, the softer the rubber head will be, and the number of pad printing, resistance to abrasion and solvent will be undermined, and hence, heightened cost and more material waste.

4. Admixture amount of curing agent and chemical reaction of silicon: e.g., mix 100g of silicon with 50g of silicon oil, after they are sufficiently and evenly mixed, add curing agent as per 2% of the total weight of silicon and silicon oil, mix again for 2-3 minutes before exhausting. Generally exhausting duration can not exceed 10 minutes; otherwise, the silicon will harden quickly to affect the quality of molding.

5. Admixture amount of curing agent and silicon reaction:

5.1. Added with 1% of curing agent, silicon can still flow within 2.5 hours, mold can be released in 6-8 hours.

5.2. Added with 2% of curing agent, silicon can still flow within 50 minutes to 1 hour, mold can be released in 2-3 hours.

5.3. Added with 3% of curing agent, silicon can still flow within 28-30 minutes, mold can be released in 1.5-2 hours

5.4. Added with 4% of curing agent, silicon can still flow within 10-15 minutes, mold can be released in 1-1.5 hours

5.5. Curing agent reaction rate is related with weather and temperature. Under 25 degree, they can be added according to the instruction or at double amount in winter or under subzero temperature.

(Note: curing agent can not be added above the 4% maximum level and the normal proportion is 2%. If more than 4% is applied, the silicon will condensate too fast for normal usage).

Above is the mixing data for silicon and curing agent, the precise result of hundreds of times of our experiments. Provided that you arrange production according to our instruction, you are sure to manufacture first class products and maximize your profit – this is not only the need of, but also our responsibility for and a satisfactory answer to our customers. We may not be the first, but we will try to be the best. The customers need is what we pursue !

pritingsilicone、移印硅胶、移印胶

相关产品推荐

-

AB双组份模具硅橡胶

AB双组份模具硅橡胶

-

仿道康宁模具硅胶 仿道康宁模具液体硅胶 仿道康宁模具液体硅胶矽胶

仿道康宁模具硅胶 仿道康宁模具液体硅胶 仿道康宁模具液体硅胶矽胶

-

仿日本信越电子灌封胶 仿日本信越电子灌封硅橡胶 日本信越电子灌封硅橡胶电子胶 日本信越电子灌封硅橡胶 电子胶

仿日本信越电子灌封胶 仿日本信越电子灌封硅橡胶 日本信越电子灌封硅橡胶电子胶 日本信越电子灌封硅橡胶 电子胶

-

移印矽利康 移印硅胶矽利康 移印液体硅胶矽利康

移印矽利康 移印硅胶矽利康 移印液体硅胶矽利康

-

船舶真空袋模具硅胶矽胶 船舶真空袋模具液体硅胶矽胶 船舶真空袋模具液体硅橡胶

船舶真空袋模具硅胶矽胶 船舶真空袋模具液体硅胶矽胶 船舶真空袋模具液体硅橡胶

-

游艇轮船真空袋模具硅胶 游艇轮船真空袋模具硅胶橡胶 游艇轮船真空袋模具硅胶橡胶矽胶

游艇轮船真空袋模具硅胶 游艇轮船真空袋模具硅胶橡胶 游艇轮船真空袋模具硅胶橡胶矽胶

-

933#移印硅胶瓦克623 933移印硅胶仿瓦克623 933移印液体硅胶仿瓦克623

933#移印硅胶瓦克623 933移印硅胶仿瓦克623 933移印液体硅胶仿瓦克623

-

硅橡胶矽胶真空袋 硅橡胶矽胶液体硅胶真空袋

硅橡胶矽胶真空袋 硅橡胶矽胶液体硅胶真空袋

-

深圳红叶硅胶厂供应缩合型液态硅胶

深圳红叶硅胶厂供应缩合型液态硅胶

-

深圳红叶硅胶厂供应半透明模具硅橡胶

深圳红叶硅胶厂供应半透明模具硅橡胶